Introduction

The Skyactive engine platform found in the ND MX-5 vehicles is a particularly complex system. Throughout our development we’ve made an effort to balance our efforts in simplifying the tuning system, as well as offering RaceROM features in the limited free space available to us in the ROM. This means our RaceROM offerings are slightly different than in other platforms as there are either simplified forms being used, or something altogether unique.

With a framework for the platform in place, we’ll be working with our dealers in order to balance the features for this platform, with the practical limits of the ECU.

| Panel | |

|---|---|

Supplemental ContentPlatform Specific

General |

Table of Contents

| Table of Contents | ||||||||

|---|---|---|---|---|---|---|---|---|

|

The Platform

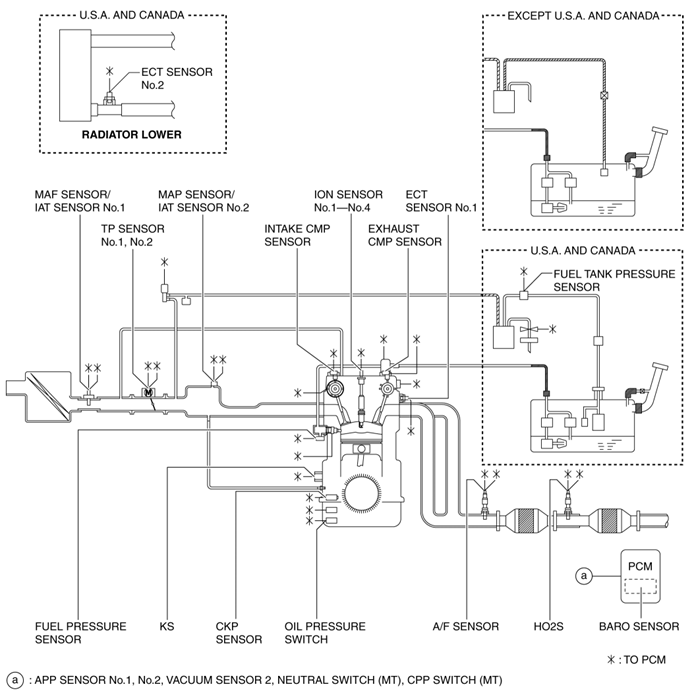

The Mazda Mx-5 SkyactivG cars use a high compression (14.0:1) 1.8L or 2.0L 4 cylinder engine utilising direct injection with a high degree of freedom of cam timing on both inlet and exhaust cams. This allows the engine to use many complex strategies to deliver high power and high efficiency for such a small capacity. The control system components are as below.

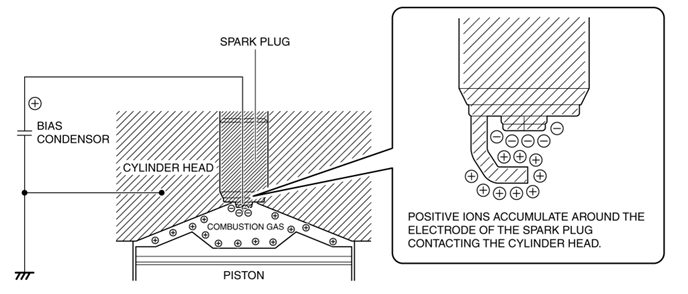

Mazda have employed ion sensing technology to model per cylinder detonation, pre ignition and air fuel ratio and uses these in many of the airflow and ignition timing strategies to preserve reliability while maintaining a high as possible performance and low emissions.

Ion sensing involves measuring the electrical current flow after the spark initially bridges the gap between the center electrode of the sparkplug and the ground strap. In the event of a misfire, no current flow can be easily detected, making it a fairly stable and accurate method of measuring misfires.

The 4-2-1 type exhaust pipes have been adopted for the exhaust manifold to create an engine with a high compression ratio.

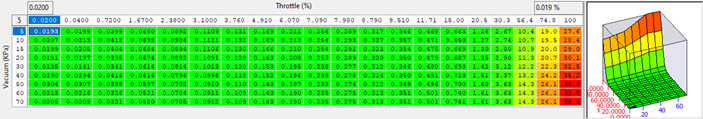

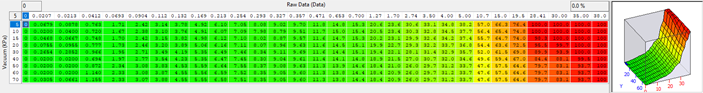

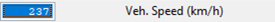

Two types of load and airflow estimation have been adopted for the intake air amount measurement to achieve stable combustion free from abnormal combustion.

- L-jetronic (The intake air amount is directly detected by measuring the amount of intake air flow using the MAF sensor.) MAF sensor adopted

- D-jetronic (The intake air amount is detected indirectly by measuring the intake manifold pressure (pressure between downstream of the throttle valve and intake manifold) using the MAP sensor.) MAP sensor adopted

- IAT sensor No.1 and No.2 adopted

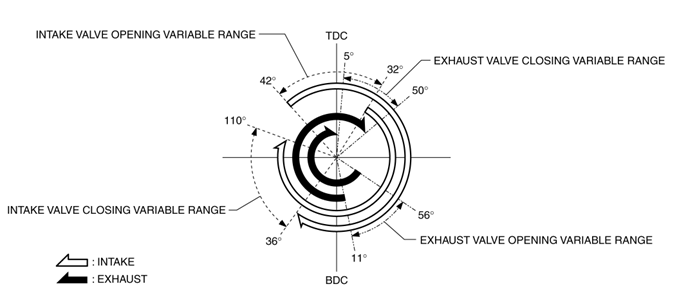

To improve the fuel economy and emission performance, an electric variable valve timing control has been adopted for the intake side, and a hydraulic variable valve timing control for the exhaust side. The electric type is adopted for the intake side to achieve expanded valve overlap and delayed closing of the intake valve (enlarged intake valve opening angle). The Hydraulic Lash Adjuster (HLA) has been adopted to achieve the maintenance-free valve clearance.

- Intake side: Electric variable valve timing control with independent CMP sensor

- Electric variable valve timing motor/driver

- Electric variable valve timing relay

- Exhaust side: Hydraulic variable valve timing control with independent CMP sensor

Engine hydraulic pressure switching control (using Engine oil solenoid valve) has been adopted to reduce the oil pump operation load on the engine.

To improve engine reliability, an ion sensor has been adopted which detects pre-ignition.

Some other features Mazda have listed as advances with their SkyActiv technology are.

Sliding resistance reduction

- Rocker arm (with built-in needle roller bearing) adopted for cam-contact area

- Reduced valve spring load

- Narrowed down crankshaft journal

- Optimized piston skirt shape

- Lowered piston ring tension

- Lowered drive belt tension

- Suppressed chain tensioner load by stabilized timing chain behaviour

- Oil shower pipe adopted

Mechanical resistance loss reduction

- Optimized oil passage

- Optimized oil pump shape

- Engine oil control adopted

Cooling loss reduction in early stage of combustion

- Piston cavity adopted

Pumping loss reduction

- Variable valve timing mechanism adopted on both intake and exhaust sides for fine control of exhaust amount and internal EGR volume

Cooling efficiency improvement

- Air seal cowl and flaps adopted

- Optimized cooling fan shape

- Optimized engine coolant passage

- Optimized water pump impeller shape

Combustion efficiency improvement

- Multiple hole-type fuel injectors

- High-pressure fuel pump

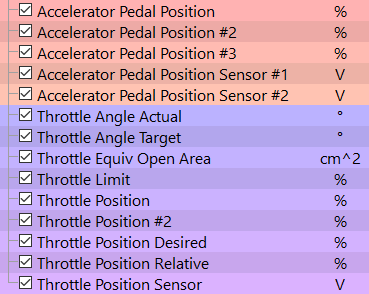

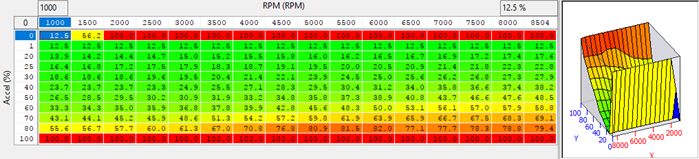

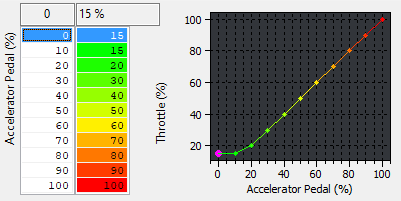

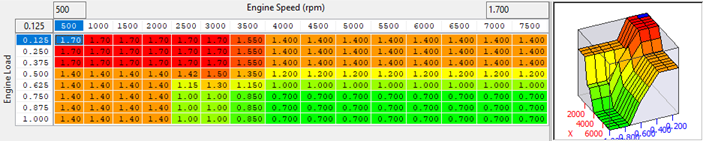

Accelerator / Throttle Control

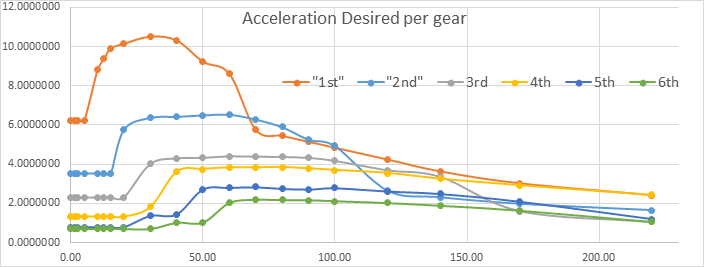

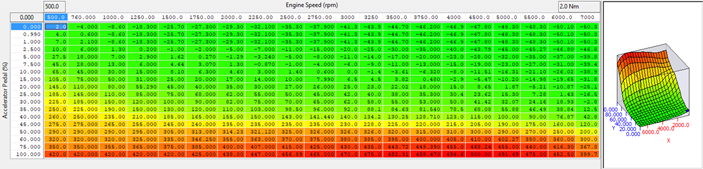

Throttle control in the ND is heavily linked to torque demand. For a more thorough investigation of how torque requests and accelerator control are linked check out our article Skyactive G - Driver Demand Acceleration Request

Throttle Limiting Map

This can be used on turbo cars specifically to prevent WOT at low pedal, as the ecu tries to get the airflow while the turbo is spooling, and then having a big throttle fluctuation as the throttle closes to regulate the airflow to the desired levels. It's nice when it works (Ford Ecoboost) but we don't have the maps to tune the response of the OEM strategy so use the limiter map.

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

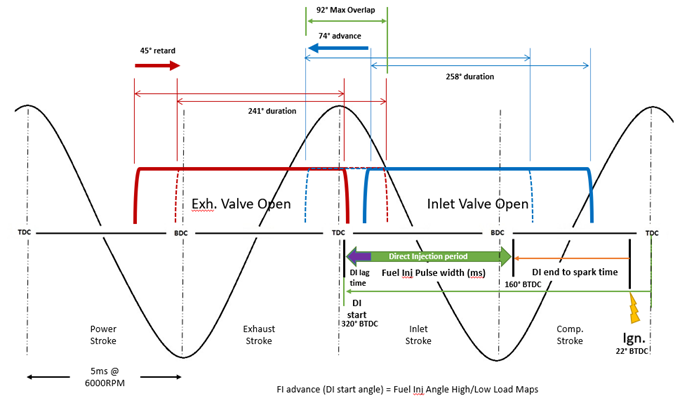

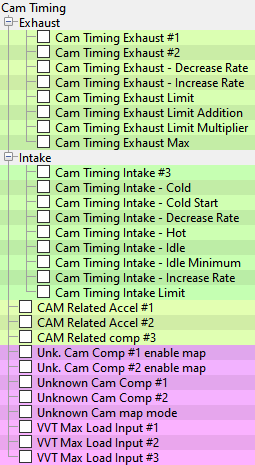

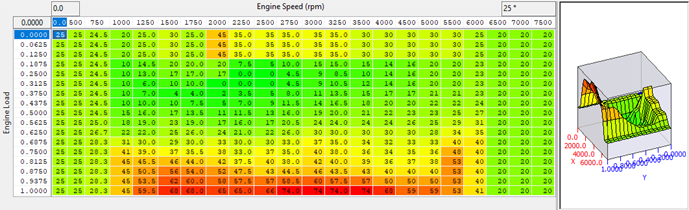

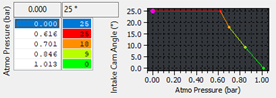

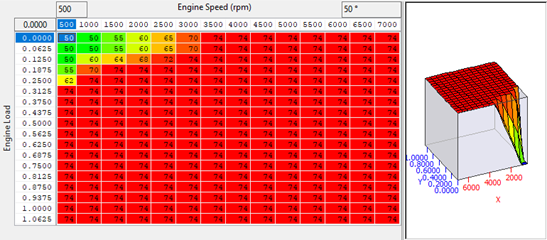

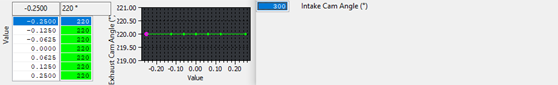

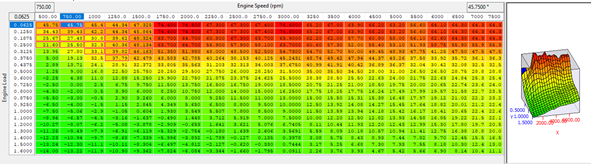

Camshaft Timing

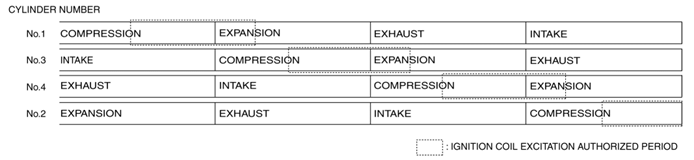

Mazda utilise an electronic Intake Cam VVT actuator to allow quick and precise wide range of movement. With a maximum overlap from intake open to exhaust close is 92° allowing for huge amounts of blow through if not correctly calibrated. In addition to using the cam timing for EGR duties, it allows the system to enact the “Mazda Miller Cycle at low loads. This cycle allows the intake valve to stay open beyond the bottom of the travel and into the compression stroke causing a slight amount of the air fuel mixture to go back into the intake manifold during the initial ~20% of the piston’s compression stroke. The benefit being a slight reduction of the effective compression ratio. They also utilise a hydraulic exhaust cam VVT actuator to allow for maximised. The basic outline of the cams and how it related to crank angle and injection period is shown below.

They allow a wide range of movement (roughly 74deg), where the target position in the map is the advance or retard from the base stop position. The VVT has different target modes, for idle, cold start and normal operating temperature and the switch point between the modes is not known yet.

| Item | Specification | |||

|---|---|---|---|---|

| Valve Timing | IN | Open | (°) | BTDC 420ATDC 32 |

| Close | (°) | ABDC 36-ABDC 110 | ||

| EX | Open | (°) | BBDC 56-BBDC 11 | |

| Close | (°) | ATDC 5-ATDC 50 | ||

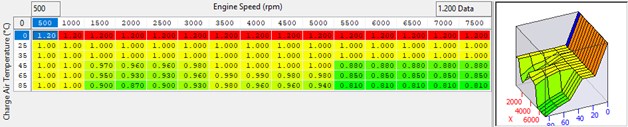

Correcting for effects of VVT

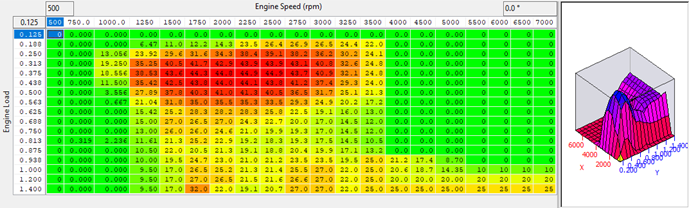

In early testing it was found that VVT Intake cam angle has a profound effect on the VE of the engine, especially with the ND's very wide range of operation (74° crank angle). So it has been necessary to make some provision for this as the ND can on occasion transition between cam maps, or (seeming) reduce the cam advance to effect torque output or avoid detonation.

This function is still in development and will include additional maps for exhaust VVT and expand on the MAP weighting map. However it is quite useable in it's current form.

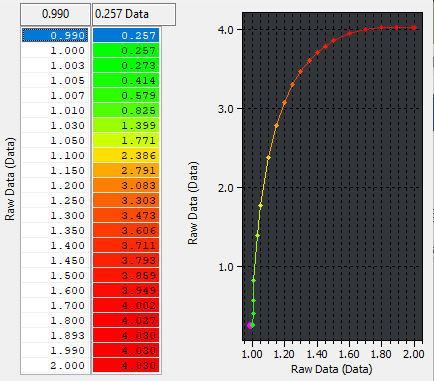

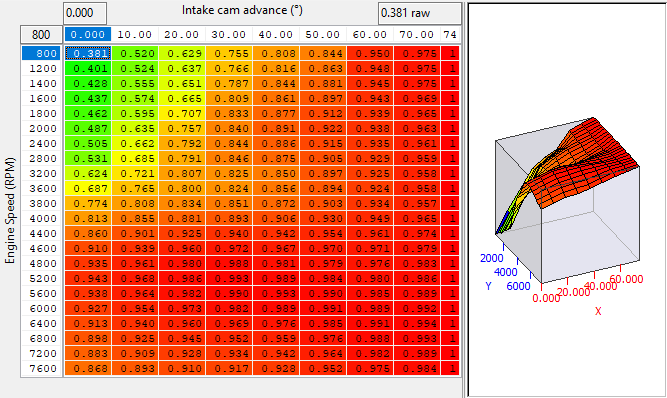

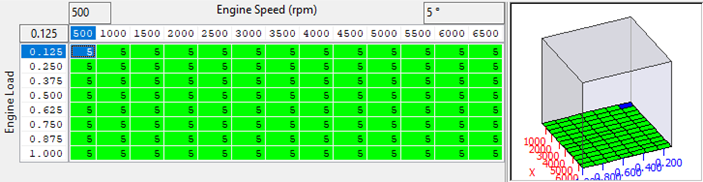

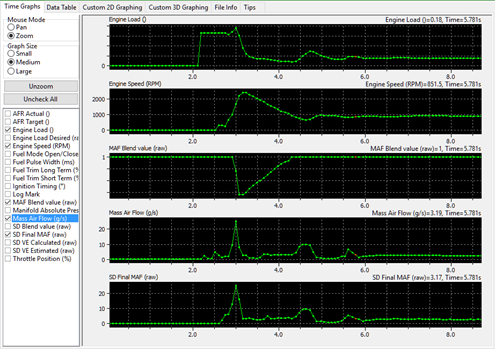

Intake Cam VE Correction

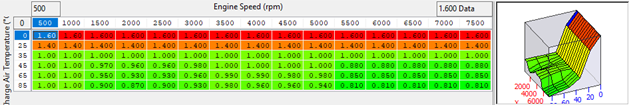

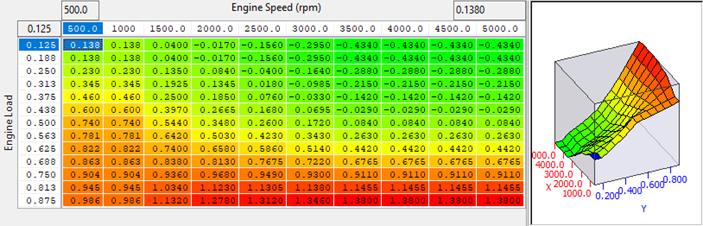

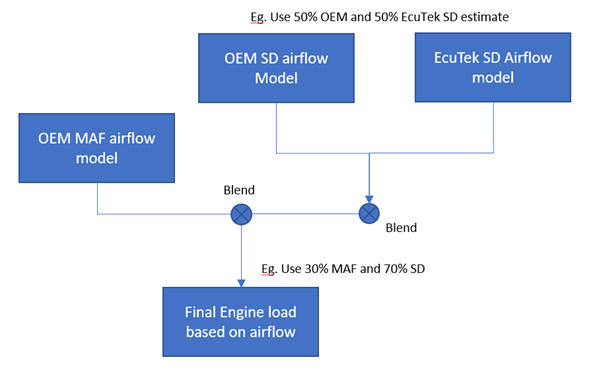

This map is a simple multiplier that is applied to the output of the Speed Density Volumetric Efficiency map.

There is no live data to specifically support this map, however when back calculating "SD VE Calculated" from the MAF sensor, the effects of the cam correction maps are taken into account. So in reasonably steady state conditions "SD VE Calculated" follow "SD VE Estimated" quite closely when properly tuned.

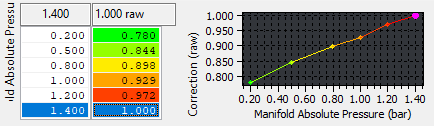

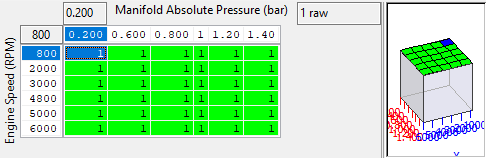

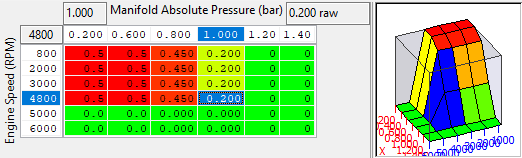

Intake Cam Correction Weighting

This effectively adjusts the effects of the "Intake Cam VE Correction" map based on Manifold Absolute Pressure, if the values in this map are lowered it has the effect of "flattening" the Cam VE Correction map, where this map returns 1.0 the Intake Cam VE Correction map is used as is, the result is as follows:

CamCorrectionFinal = 1 - ((1 - CamCorrectionMultiplier) * CamCorrectionWeighting)

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

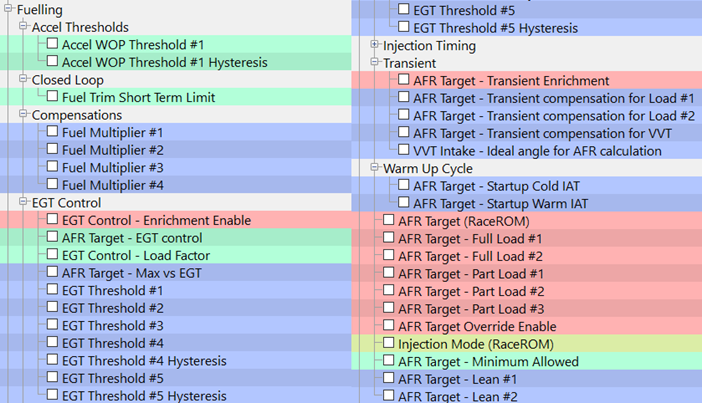

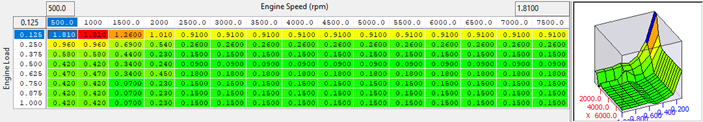

Fuelling

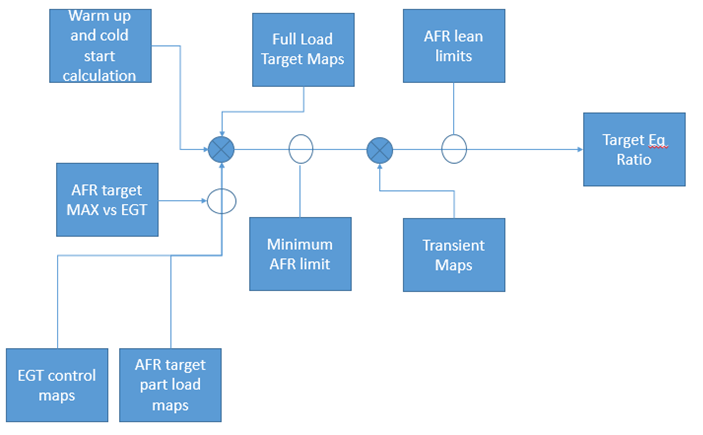

Fuel Target Tuning

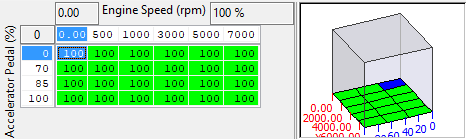

The Target Fuelling strategy for ND is complex and is based on engine load with many protection modes and temperature control methods. It is basically split into 3 primary modes start up, part load, full load temperature control as well as two different fuel cut modes with corrections and limits are applied at various points in the calculation. There are fundamental differences between NASP and FI tuning that particular attention should be paid, such as accel pedal and temperature thresholds. These are covered later in the document.

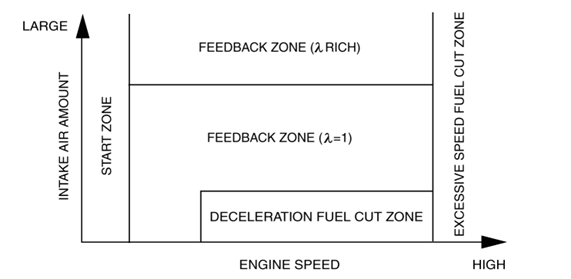

Mazda split the fuelling Control Method into zones

While cylinder fill models and lambda targets derive the injection quantity the conversion and correction of the injector open time is restricted according to the above modes.

Start Zone = RPM < 500

In this mode the injection time is set according to engine coolant temperature (low engine coolant temperature = long injection time). After start corrections are also set for a specified time according to engine coolant temperature directly after engine start

- Low engine coolant temperature = large correction

- Low intake air temperature = large correction

Feedback zone (λ = 1) = All other times

In this mode injection time is calculated as a base amount using Cylinder fill and fuel flow coefficients. It also applies corrections for

- Warm up enrichment (low ECT or AIT) after start

- Short term fuel trims (AFR Error actual to target)

- Rear O2 sensor

- Warm up enrichment at high loads

- Long Term Fuel Trims (Learned value based on average value of A/F deviation amount)

Feedback zone (λ rich) = WOP accel and EGT above threshold

- Short term fuel trims (AFR Error actual to target)

- Warm up enrichment at high loads

- Long Term Fuel Trims (Learned value based on average value of A/F deviation amount)

- EGT Corrections (Based on the accelerator pedal opening angle or on engine speed and cylinder fill.)

Fuel cuts are determined as Injection time = 0 during

- Excessive speed fuel cut zone = Above Rev Limit

- Deceleration fuel cut zone = Accel pedal closed, above decel fuel cut off (DCFO) RPM and Vehicle speed

A heavily Simplified view of the strategy is below

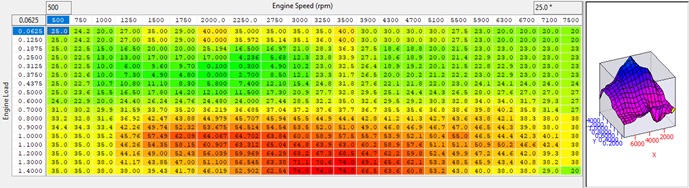

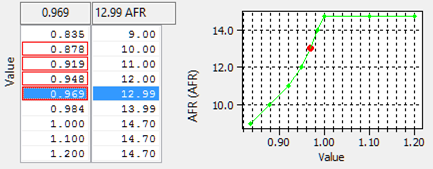

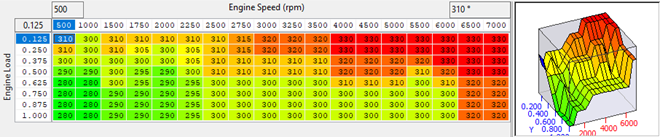

AFR Target

Our advice for fuel tuning is use the trims as your guide. Adjust your MAF/SD maps as you need to keep the trims to zero and you will be sorted.

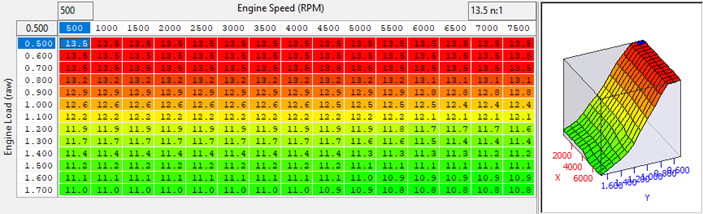

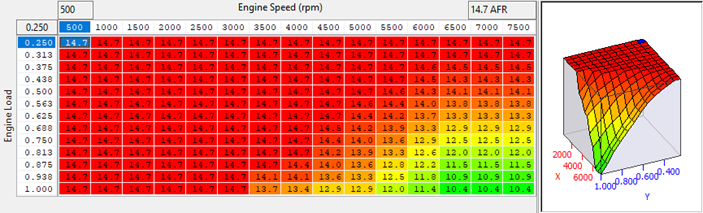

This is an AFR target table that is employed when the WOP (Wide Open Pedal) threshold is exceeded. In the OEM strategy there are 2x 2d maps (AFR Target - Full Load #1 / #2) the result of which is overwritten by the output of this map.

It is only enabled by checking the box in "AFR Target Override Enable"

Typical usage will include lowering the WOP threshold to a level that corresponds to a value that gives loads in the region of 0.8 or more. This is primarily for turbo application and used to switch to a richer target AFR that is variable with load, and prevent Lambda 1 at part pedal but significant load due to boost. On our turbo ND we lowered the WOP threshold from 93% to 35% but you should test for your selves.

The WOP thresholds can be found in the Fuelling->Accel Thresholds

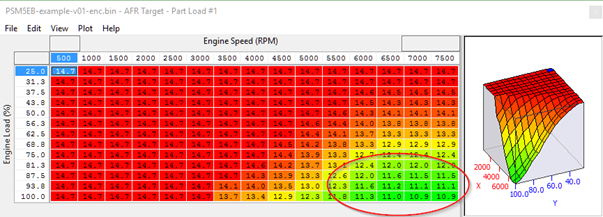

Part Load Fuel target

From our testing the ND generally runs Lambda 1 at part throttle, except when in the transient mode (a fraction of a second) and when the catalyst temperature is above the cat temperature threshold map EGT control #2, it then richens up to the 3d part load tables. It may also use the maps at part throttle (maybe at full throttle without kickdown button pressed on auto car).

The part load fuel targets are the maps “AFR Target Part Load #1 (#2 and #3)” affect the target AFR the ECU will ramp down to the target value (CAT temp goes about 826°C) so you can lean these out to reduce enrichment when at part/full throttle.

WOT AFR target

The WOT closed loop throttle is well understood but very complex. The AFR target at WOT is controlled by the 2 2d maps, along with some very small offsets for load. However, the ECU is constantly monitoring catalyst temp, exhaust temp and presumably cylinder head temp, all it appears through modelling. It will always ramp towards the richest target when certain cat temp thresholds are met or exceeded.

You can make the car run the WOT target you want by zeroing out the 3d EGT control enable table, or one of the 2d correction tables. I'm also sure that if you don't change the 3d target AFR tables that there is another temp threshold that will cause the afr target to ramp towards the values in those 3d maps.

So, to properly control the AFR at WOT you will need to alter the 2d maps, the 3d part load maps, the EGT/CatT thresholds and/or the CatT control enable maps. I will need to check what thresholds do what when I get back into the office.

You NEED to do some testing at part throttle, it generally runs Lambda 1 at part throttle once out of the transient mode (a fraction of a second) and it then richens up to the 3d part load tables, but only once the cat temp has reach 826.84degC CatT. If you put lean AFRs in those tables to make the CatT uncontrollable it will then wait until 900degC before making the target richer again using the same tables to avoid high cat temp at WOT.

On WOT, the ECU will use the 2d maps. Unless it runs into "something" it doesn't like, then it will use a number of richer maps, and if you don't edit them, you will get rich AFR on WOT. There are maps that provide a different target like the 3d maps *that are not normally used at WOT* and there are also 2 other 2d maps that are used depending on the cat temp and other factors, plus a load of other compensations that sometimes get applied.

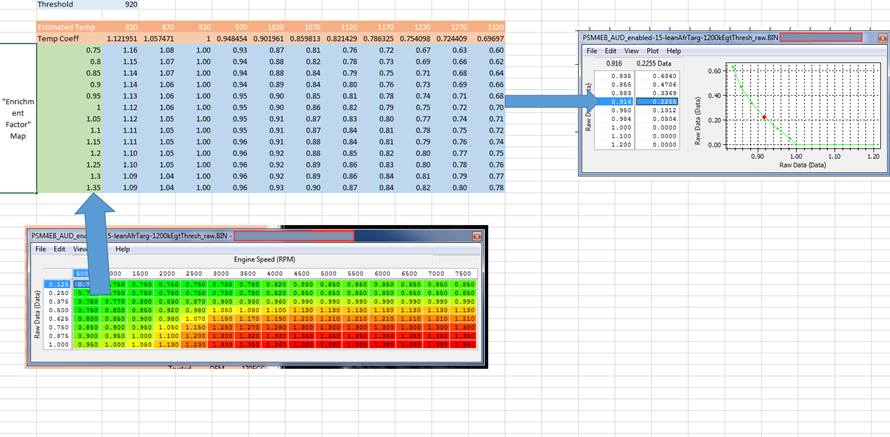

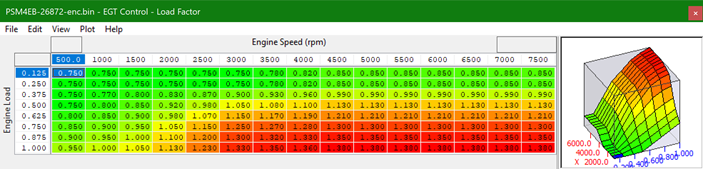

Temperature Control fueling

There is a comprehensive temperature control strategy employed in ND and we have defined several maps that will richen the target for high catalyst, uego or estimated exhaust flange temp. These maps are in the Fuelling->EGT Control category.

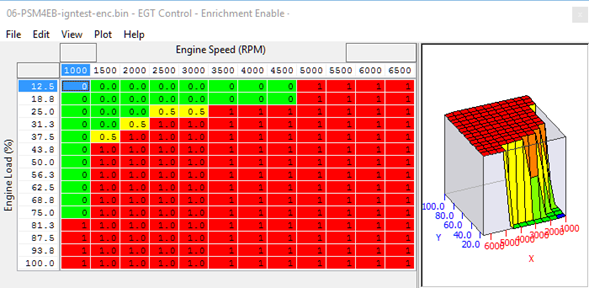

The "EGT Control - Enrichment Enable" map will change how much enrichment gets applied by outputting a multiplier.

Typically back to back runs will bring the cat temps up and the ECU tries to fight this with richer AFR, so you may want to keep this in place for the end tune sent out for customers but disable for testing.

As previously discussed when not running stoich because the CAT temperature is high the part load tables are used. It is believed that these are still used at full throttle so would recommend to change the values at high RPM and load.

If part load maps target AFRs are excessively lean and make the Catalyst temperature uncontrollable the RGT control strategy will then wait until EGT Control #4 is reached (OEM is 900degC) before making the target richer again using the AFR target MAX vs EGT tables to avoid high cat temp (does the same at WOT).

If you put 0.5 in this map the final AFR target would be the average of your normal map value (from the 2d WOT tables for example) and the values in the right hand column of the AFR Target _EGT Control Map. If you fill this table with 0 there will be no high temp enrichment from this strategy. The 3d "part load" AFR target tables are not used unless the temperature goes above 827deg, but that doesn't stop them from also being used at WOT at high cat/egt temp.

You can see from that map that one of the values used in the calculation is the 920 degrees and that if the temp is below this the AFR target is still 14.7 which is a maximum, so it would still allow 12.5 target.

Then that final enrichment is weighted by this map:

When this strategy is active you need to look at the AFR Target - EGT Control map, the numbers in the left column are an EGT target correction factor, and if you raise them for a given AFR you will see less enrichment, if you lower them you will see more enrichments. The output of this is used instead of or on top of the Part load maps so changing these might lower the target AFR as well (though not the way its shown here the changes here are to prevent it going rich at high loads).

Appropriate EGT and Catalyst temperature control

It is recommended to alter the Selected minimum AFR targets as opposed to the EGT thresholds, if you change the EGT thresholds #2 #4 and #5 by a small amount (say 50°C) to raise or lower the temperatures when the enrichment maps for EGT control are used the risk of catalyst cooling strategies may not give adequate temperature reduction in time, this is more risky as using the above methods you can maintain a leaner AFR until the catalyst temp gets very high and then target a much richer AFR.

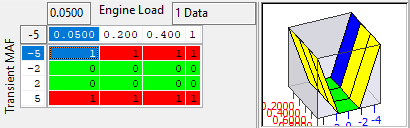

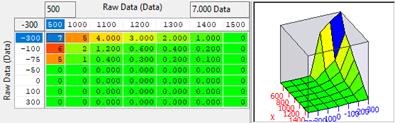

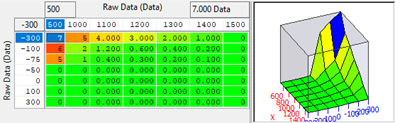

Transient Fueling

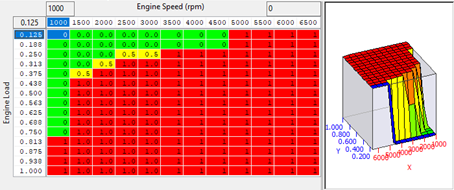

It does appear that the transient maps are essentially an accel pump, If you need to make it last longer or put more fuel in you should first try increasing the AFR Target – Transient Enrichment, which appears to be a global multiplier. The axis is likely delta throttle however currently unknown

If you need to try enrichening or enleaning a particular load or RPM point adjusting the AFR Target Compensation for load maps #1 & #2 is the next step, its believed these are a % correction value to the FR correction amount.

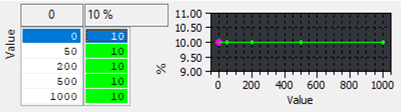

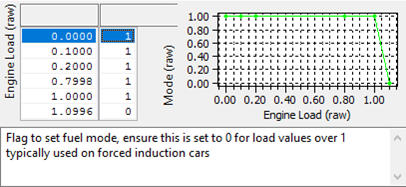

Injection Mode (RaceROM)

The injection mode maps are involved in the desired engine load calculation and should not need to be changed.

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

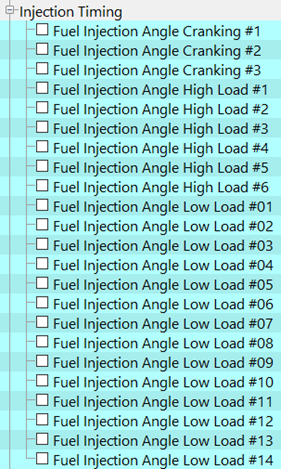

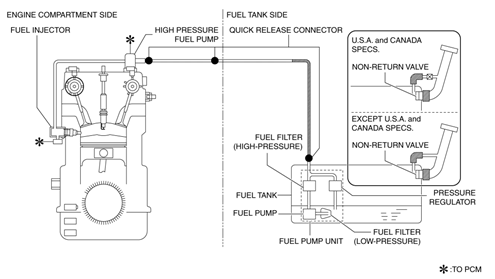

Fuel Pressure Control

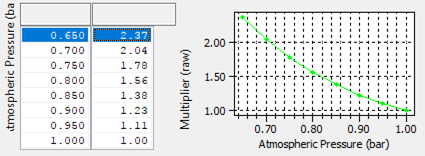

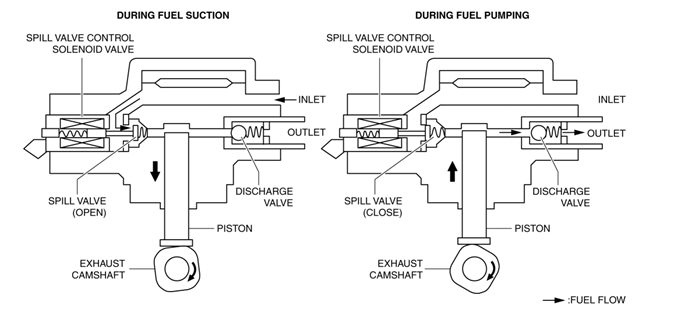

The Mazda ND has low and high pressure Fuel Pump and rail system set up as per the diagram below, it’s a fairly standard set up using a return less low pressure system with a pressure regulator in the tank (4.5bar base control pressure not manifold referenced).

The low pressure side is a common design style and feeds the high pressure fuel pump directly. The high pressure Pump works from the exhaust cam on a 4 lobe pump drive with solenoid spill control.

Fuel pressure is derived by the reciprocation of the piston made by the cam installed on the rear end of the exhaust camshaft. Based on the control signal from the ECU, the spill valve control solenoid valve opens and closes in the high pressure fuel pump at a desired angle, the drive currents would use a similar peak and hold style output but this is not covered in any maps or documents currently..

If the spill valve control solenoid valve malfunctions and the fuel pressure exceeds the specified value, the relief valve opens to assure safety.

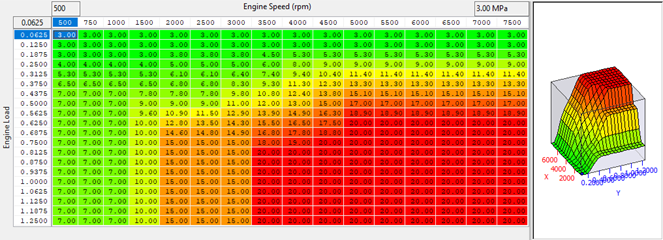

High Pressure Fuel Pump Pressure Target

The High Pressure Fuel Pump (HPFP) has man different operating modes which are not yet understood, There are definitely different target for cranking and after start that are implemented to attempt to improve atomisation when cold. There are fuel pressure logging parameters that can be used to monitor the achieved pressure and the target is set by the Pressure target 1-5.

Fuel Pressure – Target #1 - #5

These should be increased to improve the fueling capacity or if experiencing misfires due to injection quantity or piston crown fuel impingement. They are engine load and speed dependant and care must be taken that the relief valve set pressure is not exceeded as valve wear will occur very quickly and cause pump malfunction.

Idle

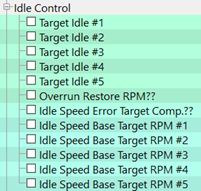

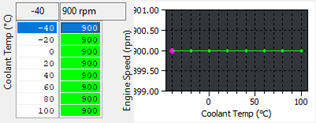

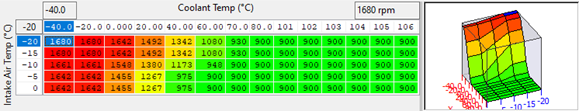

The Skyactive cars use the electronic throttle ignition angle and cams for idle control there are many complex idle control. The also attempt to balance the airflow demand using torque calculations so accurate frictional torque and combustion efficiencies help with stable idle.

Typically the issues that occur are involved with forced induction and return to idle stall or idle oscillation/hunting with accessories switching on/off. While the root cause of the oscillations are not known there are some suggestions on how to combat the idle surge and the overrun recovery.

Idle Hunt can be caused by improper torque estimation, bad airflow estimation and hence torque demand or swapping from idle ignition control to normal running mode.

- The first thing to try is to make sure that the idle speed when it raises that it doesn’t not go onto the main ignition timing maps, try lowering the main timing maps (knock limited VVT on) to the same amount that is maintaining the equivalent RPM at idle.

- The torque demand maps can also be adjusted to stabilise the idle and improve the overrun RPM drop issue.

- The target idle compensation maps can be raised as in some ROMs this has helped.

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

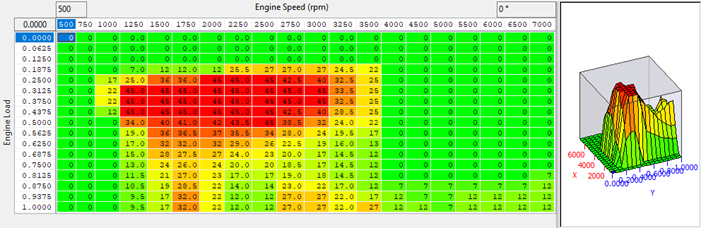

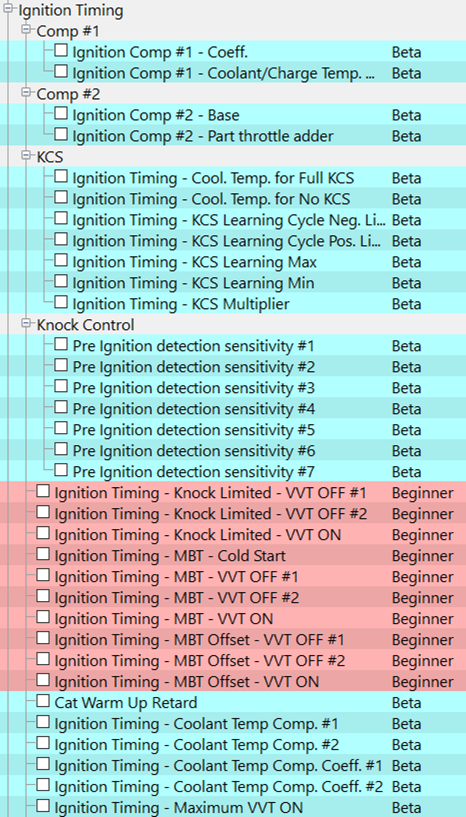

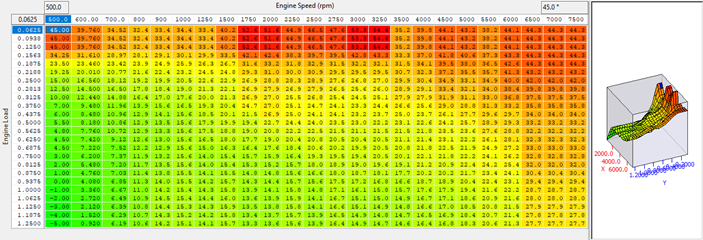

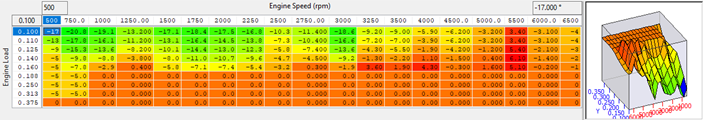

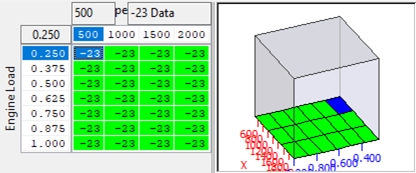

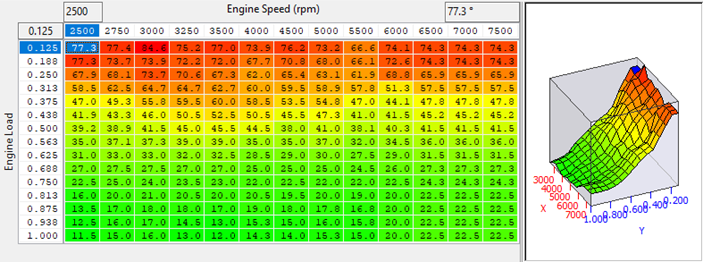

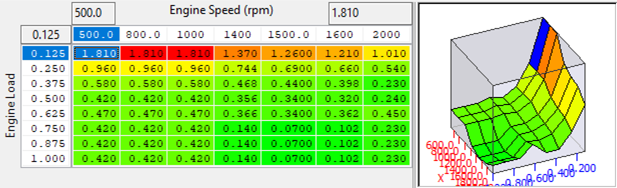

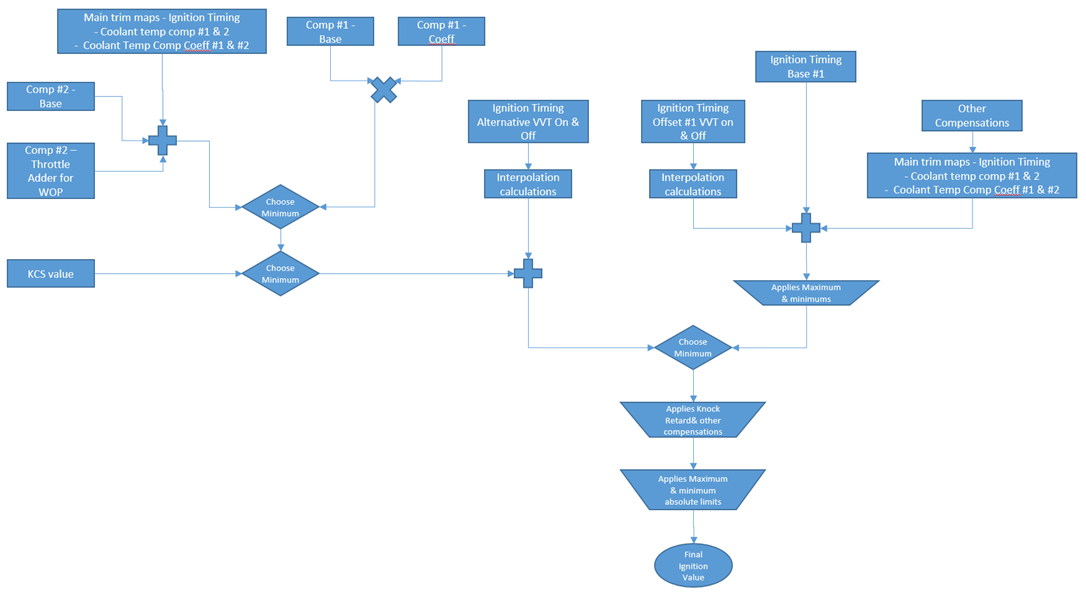

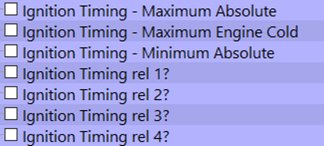

Ignition

Regarding the ignition control, please look at the example ROM. The reason the alternate maps control the ignition is because they have lower values, and it always chooses the lowest. You will notice that the Knock Limited map is lower at higher loads then the Base map, the offset is applied full time we suspect to assist in things like CAT temp emissions or engine condition etc.

For most vehicles, the best way to tune the ignition would be to use the knock limited map and keep an eye on the timing value to make sure that even at light load the timing is not too high. What will happen is that when you increase or decrease the knock limited map it will use the lower value (between base and alternate) but if there is no knock it will feed timing back in up to the base (plus offset) value. If you want more timing add it to the knock limited map until it uses the base then add to the base as well.

So if you want to run 1 map, (we chose the base map in the example ROM for the added resolution), you need to ensure that you zero the corresponding offset map, apply those offsets to the base map, then copy all the values from the Alternate maps that are otherwise lower than the base maps. If you then add 10deg to the Alternate map you will always be on the base map. At this time we have not yet determined how KCS Learning impacts these maps.

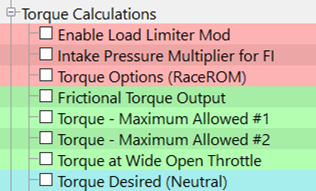

EcuTek’s advice is that you should only tune the "Knock Limited" maps for higher load, and the "MBT offset maps" if you want to adjust very light load timing. Do not adjust the base maps, as these are Maximum Best Timing (MBT) maps and employed in the torque calculations that form the basis of many of the things the ECU is calculating. Things that influence the MBT timing are doing just that, and not really critical to tuning on load for forced induction. You need to concentrate on the "Knock Limited" maps.

Similar to other platforms the ND MX-5 runs off the lowest of the MBT (+ offset) or knock limited maps. There is no need to run more than MBT and you can't run more than the knock limited ignition, however, be aware that these maps will have no doubt been calibrated for a specific octane level, and the ECU provides the facility to pull the timing up or down depending on what it thinks the overall knock/octane situation is (simplification of course).

Due to the many things that are pulling the timing up and down it's normal to find your final timing values not agreeing with map values, as the map values really are just the starting point, however making relative adjustments to the "alternate" maps definitely shows up as changes in the final value.

We know the car runs in a variety of injection modes and are fairly sure that these involve changes in ignition, possible significant changes but without a little more live data to back up what we're are seeing it's hard to determine what's going on. This will no doubt be an area of further research.

| Control Zone | Control Condition | Ignition Method |

|---|---|---|

| Start Zone | Engine speed is less than 500rpm | Engine Starting |

| Normal Zone | Engine operation except start zone | Cycle estimated ignition (Determines ignition timing adding each correction to basic spark advance |

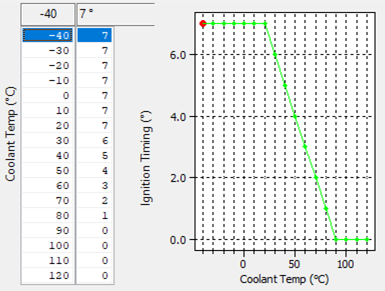

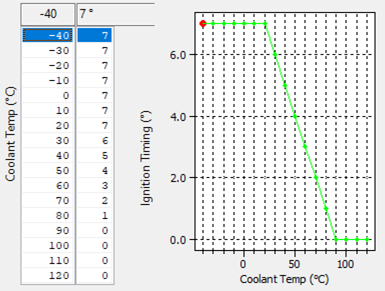

Ignition timing method table A: Ignition timing Base, B: Correction for ignition timing

| Contents | Calculation Method or Determination for Ignition Timing, Spark Advance and Correction | Control Zone | ||

|---|---|---|---|---|

| Start Zone | Normal Zone | |||

| Starting Ignition | Determination based on engine coolant temperature | A | ||

| Cycle Estimated Ignition | Basic Spark Advance | Set value according to engine speed and charging efficiency | A | |

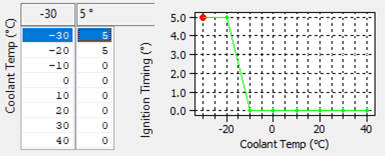

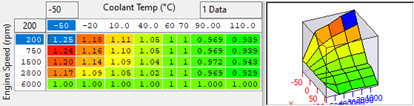

| Correction | Engine Coolant Temperature Spark Advance Correction | Ensures combustion stability when coolant temperature is low. According to engine coolant temperature High Charging Efficiency, Low Engine Coolant Temperature = Large Correction | B | |

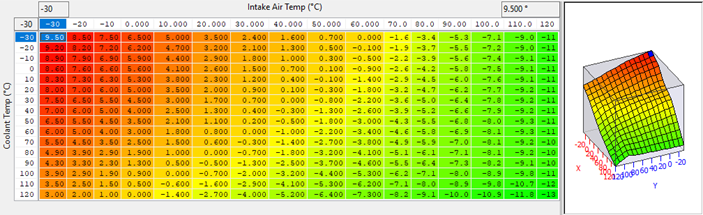

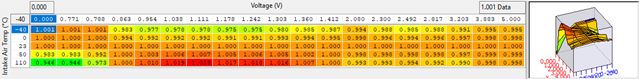

| Intake Air Temperature Correction | Suppresses knocking when engine intake air temperature is high. According to engine intake air temperature and engine coolant temperature High engine intake air temperature, high engine coolant temperature = Large Correction | B | ||

| Warm-Up Promotion Spark Retard Correction | Activates catalytic converter earlier. Maximum 50s after engine start Engine coolant temperature = Correction | B | ||

| Torque Reduction Correction | Reduction of shift shock, traction control, or suppression of vehicle vibration. Based on torque reduction request from TCM or DSC Large reduction request = Large Correction | B | ||

| Knocking Spark Retard Correction | Knocking Suppression Acceleration when charging efficency volume increases (acceleration amount) is given value or higher. Large acceleration amount = large correction | B | ||

| Valve Timing Correction | Ensures combustion stability. When phase difference changes due to electric variable valve timing control wand hydraulic variable valve timing control. Correction according to change in phase difference | B | ||

The ECU energizes the ignition coils according to the ignition timing calculated from the engine operation conditions and the igniter energization time. The igniter energization time (ignition coil energization time) is determined according to battery voltage and engine speed.

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters • Ignition Timing (°) – Current actual ignition timing in degrees BTDC, negative means ATDC |

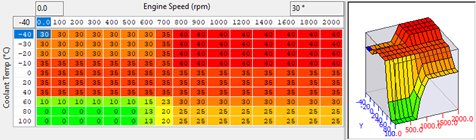

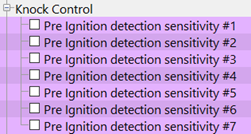

Knock Correction (KCS)

The knock control and ion sensing systems in the ECU are designed to detect engine knocking condition (pre-ignition) due to the high compression ratio and also to monitor the combustion condition in the cylinder during combustion. It does this by measuring the ion current generated during combustion as an electric current by applying voltage to the spark plug and amplifying it in the ion current detection circuit integrated in the ignition coil, the diagram below illustrates the process

After the spark plug discharges, voltage is applied to the centre electrode and ion current generated inside the cylinder from the beginning to the completion of a combustion is detected. Because the ion current is a very small, it is amplified in the ion detection circuit and sent to the ECU for processing.

The generated ion current varies depending on the actual combustion process and varies similar to the combustion/pressure inside the cylinder. The ECU determines an abnormal condition if ion current is generated outside of the during a normal combustion window. The ECU can then make adjustments to timing and effective compression ratio to try eliminate the pre ignition or knock issue.

If the engine is running off the knock limited maps, but isn't experiencing knock, the ECU has the facility to increase the ignition advance. From our experience the OEM strategies are very good at picking up detonation, so don’t be put off by letting it have some authority to advance the ignition. In much the same way as the BRZ has "advance" maps that it can use to increase the base map timing (Subaru work on the basis that MBT timing is base timing + full advance timing).

What is currently not well defined (due to limited live data) is the difference between short and long term correction and how that gets applied or stored. If you monitor the KCS value I think you will see an idea of relative learned knock correction, and the knock retard is the final value including learnt and instant retard.

The final KCS retard value is compared to the other addition coefficients as per the previous ignition timing diagram and the lowest of either is then added to the knock limited timing amount.

| Column |

|---|

Map List |

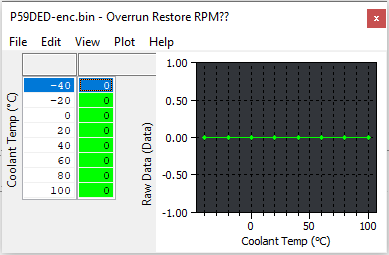

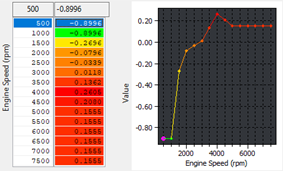

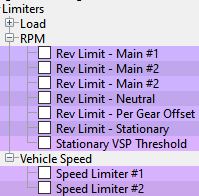

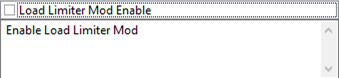

Limiters

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

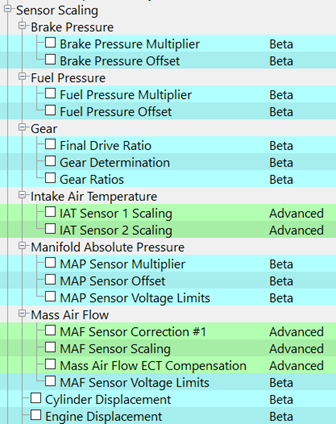

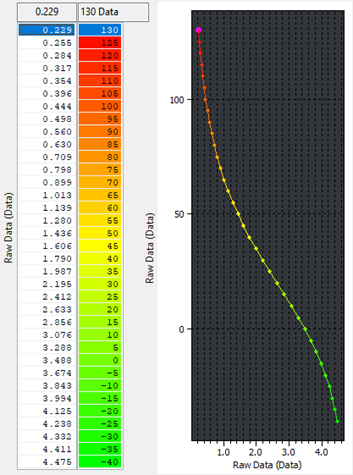

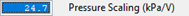

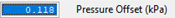

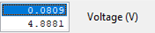

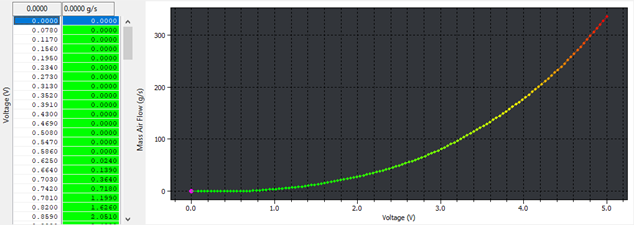

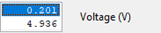

Sensor Scaling

Adjusting sensor scaling appears to behave similarly to other platforms in that you should scale the relevant voltage limits or scaling values in order to suit the new sensor.

| Column |

|---|

Map List |

Misc.

Alternator Control

The MX5 ND has a smart alternator that in some case uses and i-Eloop system, Mazda i-ELOOP is a regenerative braking system. Using this, The vehicles transfer energy that is lost during braking to a specially designed alternator. This alternator takes these surges of energy and directs them to a capacitor. This capacitor charges in seconds and distributes the electricity to necessary systems and features of the vehicle. With these systems charged through the use of braking, this takes a lot of pressure off the alternator to leech power from the engine.

Therefore, the engine salvages a lot of fuel that would otherwise be used by the alternator, improving fuel economy generously in the process (Courtesy of Mazda https://www.marketplacemazda.com/blog/what-is-mazda-i-eloop-and-how-does-it-work/).

There are maps use to control and estimate the amount of torque used when charging the capacitor at different currents and these torques are included in torque demand and actual calculations. The complete function is not currently known however currents can be altered to achieve different torque at different speeds. These maps should not need to be altered.

To assure Idling stability, controls the generator output voltage to the optimum amount according to the engine operation and electrical load conditions.

The PCM determines the engine operation and electrical load conditions based on the input signals from each control part. It then uses this information to control the energization time of the generator field coils.

Determination method for target excitation current

- Calculates the target excitation current according to the generator target output amount and the generator rotation speed.

- The generator target output amount is calculated according to the target battery voltage and battery voltage.

- During deceleration fuel-cut, the ECU increases the generator output amount and stores electricity in the battery/capacitor. In conditions other than deceleration, only the required amount of electricity is charged according to the battery status to lower the load on the generator.

Determination method for field coil excitation time

- The ECU increases or decreases the field coil excitation current by sending a duty signal to the power transistor built into the generator.

- The field coil energization current changes according to changes in the power transistor excitation time. This is accomplished by changing the duty signal duty ratio. For example, when the battery positive voltage drops, the duty ratio of the duty signal sent to the power transistor is larger, increasing the field coil excitation current.

| Column |

|---|

Map List |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters

|

| Warning |

|---|

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

Retail customers ** If you have any doubt that you do NOT have the experienced required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner to use it for you ** |