18.1 MPI

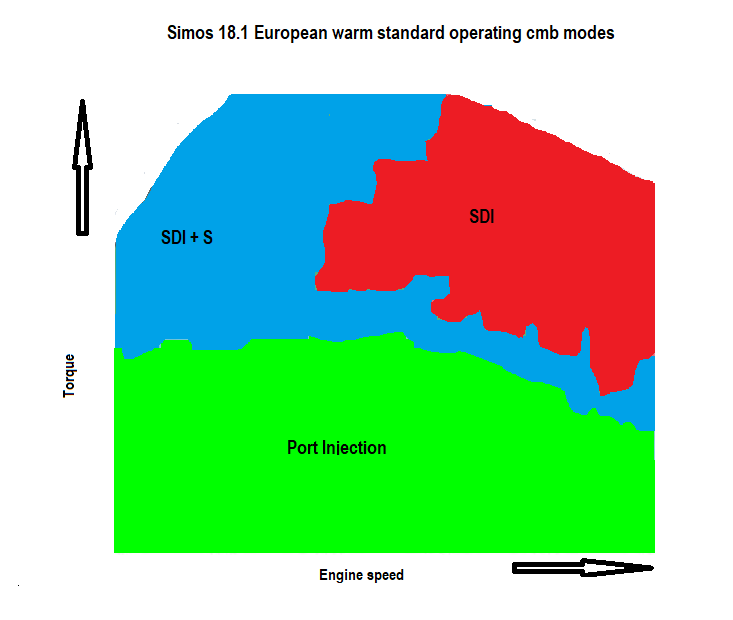

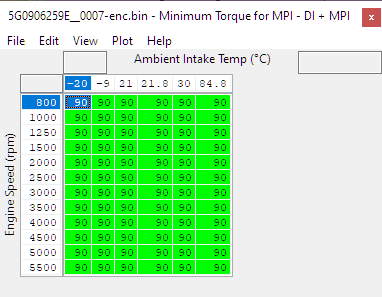

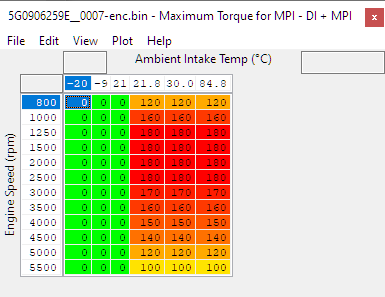

Using the tables Maximum or Minimum Torque for MPI - DI + MPI set the torque limits you desire. Min and Max Torque thresholds can also be set in MPI only and Scavenging mode.

You can adjust the hysteresis for the threshold torque (relevant to the standard operating point) via. Torque hysteresis SDI+MPI, Suction DI or MPI Only

Monitors:

- Combustion Mode

- Combustion Mode Request

- Torqune Ind. Request - Fast / Slow

Minimum Torque for MPI

Maximum Torque for MPI

18.10 MPI

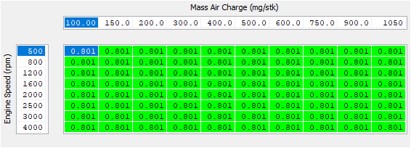

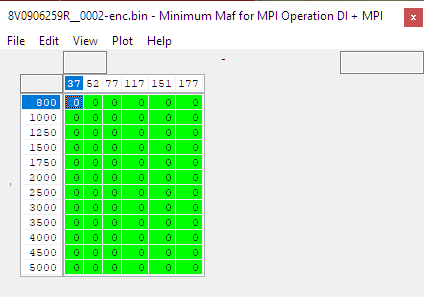

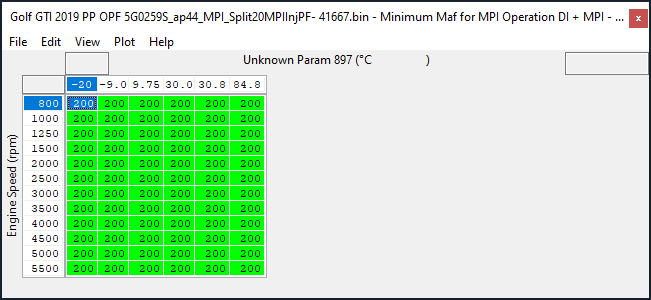

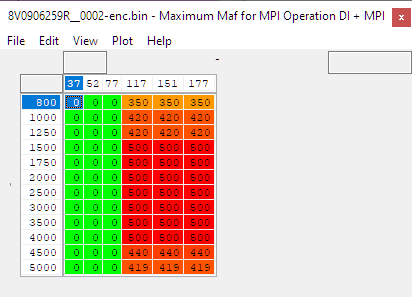

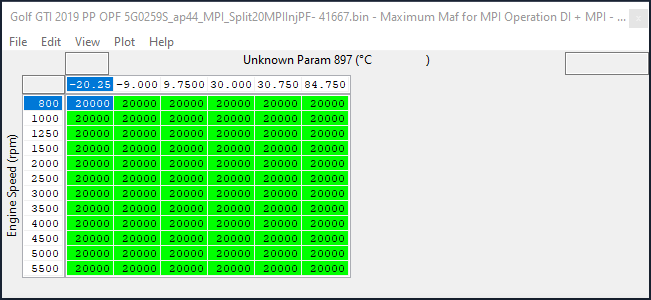

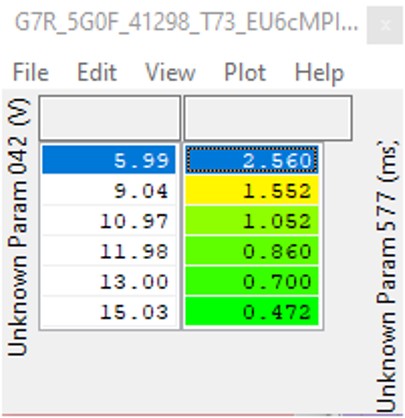

Using tables Maximum or Minimum Maf for MPI and DI + MPI, set the minimum and maximum torque you wish to use in DI and MPI mod

Min and Max Maf thresholds can also be set in MPI only and Scavenging modes. Torque Hysteresis into the threshold torque, relevant to the standard operating point can be adjusted via. Airflow hysteresis, Scavenging, DI Stratified Scavenging, DI + MPI, Suction DI or MPI only Monitor via Combustion Mode, Combustion Mode – request and Torque Ind. Request – Fast/Slow.

Minimum MAF for MPI Operation

Maximum MAF for MPI Operation

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|