Introduction

The EA888 Gen 3 (EA888.3) is a global engine suitable for MLB (Modularer Langsbaukasten/Longitudinal ) and MQB (Modularer Querbaukasten/Transverse) platforms, capable of meeting the latest emission and fuel economy targets in different markets

In the Europe, the new MQB EA888 Gen 3 engines were introduced to Volkswagen Golf, Skoda Octavia, Seat Leon and Audi A3/S3 vehicle.

A Simos 18 Engine Control unit was utilised in order to control the features of the engine. The Engine family has two different sizes currently (1.8 litres and 2.0 litres) with the larger (2.0l) family offering both a lower output (but high compression) option and a high output (Lower compression) option.

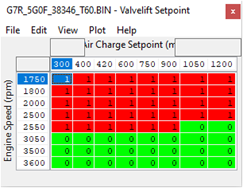

Currently Gen 3 EA888 engines, used in MQB cars covered in this document, use an exhaust only AVS (Audi Valvelift System).

Supplemental ContentPlatform Specific General |

Table of Contents

Summary of Software

ProECU software has been introduced to allow reprogramming of the factory ECU in order to tune the necessary components of the calibration, allowing for modifications and increases in power. Pro ECU software filters several thousand OE calibration maps into a comprehensive set of maps, selected to all allow the tuner to tune the engine with similar ease, found on a standalone replacement ECUs.

The software allows easy control over most factory parameters including:

- Boost targets and wastegate control

- Target AFR

- Ignition timing and knock control

- Valve timing and lift control

- Fuel delivery including fuel pump calibration (using the same style pump as OEM)

- Airflow Measurement and fuel compensation

Tuning should be carried out by suitably trained individuals.

Use this document is a guide. Changes to any calibration is at your own risk.

Changes involving the evaluation of full engine load, should be carried out in the safety of a chassis dynamometer by trained personal.

The base engine should be deemed in a serviceable state of health as well as the dress kit bolted to it before attempting to tune it etc.

For the best results, ensure the engine is run on the best commonly available fuel (in the EU, RON 98 or greater)

This document is also work in progress.

Programming

For information on how to program as well as flash recovery, check out.

For more software guides check out:

Tuning Guide

The Simos 18.X Engine Control Unit (ECU) requests and outputs torque via a fast path and a slow path.

The fast path includes the following attributes.

- Ignition control.

- Fuel setpoint and lambda control.

- Fuel shut off.

The slow path includes the following attributes.

- Load demand via air setpoint

- Throttle setpoint

- Turbocharger actuator set point.

- Cam setpoint.

Tuning the ECU for more torque involves several operations and involve raising the load limits on the slow path and optimising the fuel and ignition settings on the fast path.

Adjusting the Threshold Limiters

Setting proper limits on what the engine can and can't do is an important step to start with. In some cases the limiters will step in when you attempt to make additional power which can slow or even halt forward progress on a tune. The important thing to remember is that these limiters aren't just in place to stop you from making power. They exist to protect various vehicle components and some common sense should be used when raising them. For example raising the allowed Exhaust Gas Temperature to high can lead to a shorter life span on the vehicle's catalyst etc.

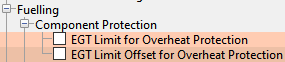

EGT

- EGT Maximum Relates to the maximum catalyst temp and is set at a factory 950 deg C

- EGT Limit for Overheat Protection Relates to the turbocharger turbine protection

Rev limit

- Engine Speed Maximum Set as desired from factory default of 6800 rpm

- Engine Speed Limit for Stationary Vehicle AUTO/MT/DCT, usually set at ~ 3800 rpm from factory

- Engine Speed Limit for VVL System High/Low/by Gear Set to match Engine Speed Maximum factory redline.

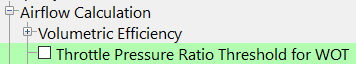

Throttle Pressure ratio Limits

- Throttle Pressure Ratio Threshold for WOT - To force the throttle open to WOT, you need to reduce the pressure ratio around the point where there is just about positive pressure.

It will need to be blended and refined from the example below, to not have the throttle slam open at light loads or pullaway

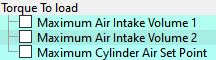

Air limit

- Maximum Air Intake Volume 1/2 ( No lift or Lift) Set to a maximum beyond what is output from Reference Air Charge.

- Maximum Cylinder Air Set Point Alter if more than 2000 mg/stk is to be consumed through the engin

Intake pressure limit

- Manifold Pressure Set point Limit Set this value higher than the highest desired boost expected in the manifold. Default is 3000 mbar ( 2 bar gauge)

- Maximum Intake manifold Pressure Setpoint Set this value higher than the highest desired boost expected in the manifold. Default is 2500 mbar ( 1.5 bar gauge)

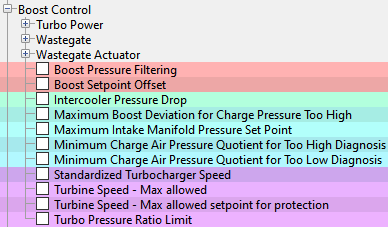

- Minimum Charge Air Pressure Quotient Too High for Diagnosis Adjust to clear maximum boost achieved.

PUT to Intake pressure deviation limit

- Maximum Boost Deviation for Charge Pressure too high Set to ensure transients into target boost has enough head room.

- Charge Air temperature Limit

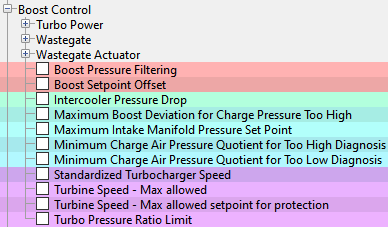

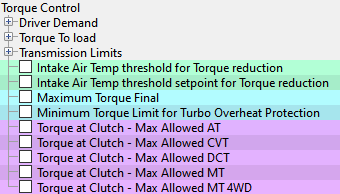

- Intake Air Temp Threshold for Torque reduction Turbo Charge Air temperature threshold - To be raised due to operating higher operating pressure ratios.

- Intake Air Temp Threshold setpoint for Torque reduction Turbo Charge Air temperature threshold set point. To be raised due to operating higher operating pressure ratios.

Turbo limits

- Minimum Torque for Turbo Overheat Protection Option to set higher than stock.

- Turbo speed Max Recommendation to set beyond 176K rpm.

- Turbo speed Max for protection Recommendation to set beyond 161K rpm.

- Turbo Pressure ratio limit Set to beyond target PR.

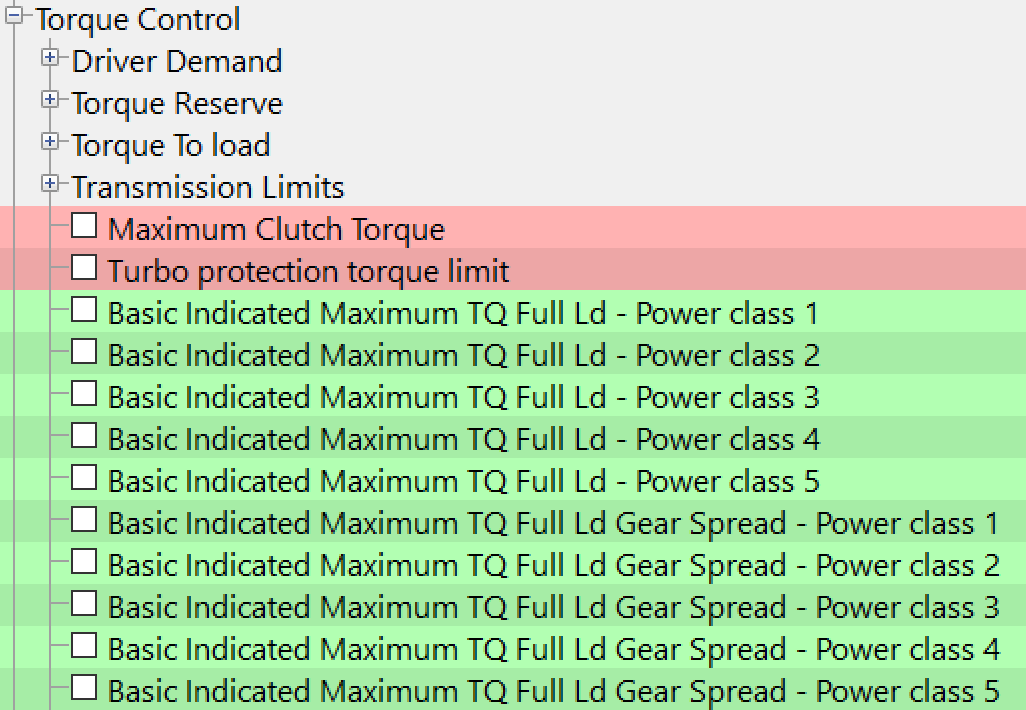

Maximum indicated torque limit

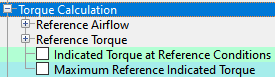

- Maximum Reference Indicated Torque Set this to a maximum.

Basic indicated Maximum TQ Full Ld - Power Class 1-5

- Basic indicated Maximum TQ Full Ld - Power Class 1-5. Set these maps to a maximum on some Cal ID's they will be set at 1024Nm as standard.

- Basic indicated Maximum TQ Full Ld - Gear Spread 1-5. Set these maps to a maximum on some Cal ID's they will be set at 1024Nm as standard.

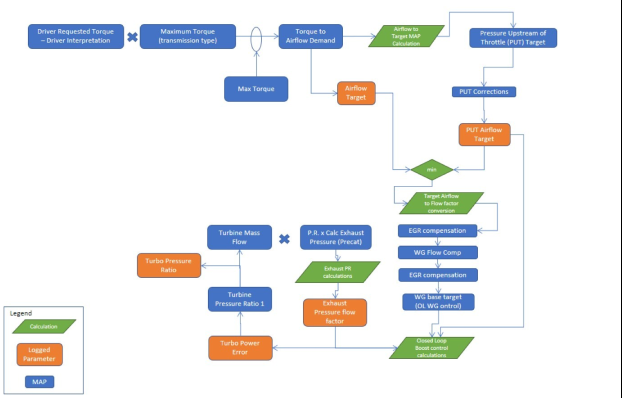

Vehicle Speed limit

- Vehicle Speed limit All. Set to desired maximum.

Airflow Determination

Airflow determination comprises of several calibration tables that allow the load of the engine to be increased for a given set of engine speeds.

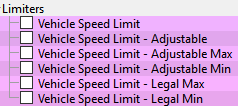

Increasing the boost via an increase in air mass set point can be summed up by the following illustration.

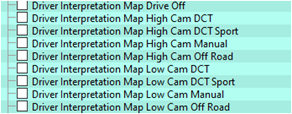

Driver requested torque This is a function of the Maximum torque request factor by the driver. The driver request factor comes from the pedal via the parameter "Driver Interpretation Map" and is often scaled to be nonlinear by the manufacturer with a leading edge at the low loads, low rpm breakpoints.

There are several of these Interpretation tables and they depend on the driving mode of the vehicle (i.e Eco, Normal, Sport) and the cam position (low or high), as well as the transmission type

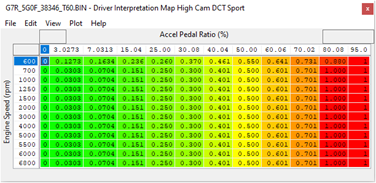

An example of a typical Driver Interpretation Map from the example rom is shown below (recalibrated to be more linear).

Important Logging Item Accel Pedal %

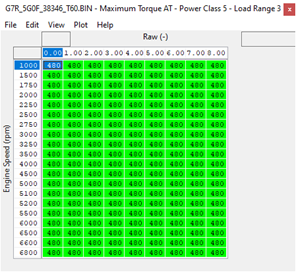

The output of the Accel Pedal ratio tables, is multiplied into the following parameter, Maximum Torque AT/MT depending on the power class and load range. These tables can be condensed to have the same values. Below is an example of a typical Maximum Torque (AT) map.

In RaceROM version 3 these values can be tuned per map switch mode and have further multipliers for accel pedal. VW AG EA888 RaceROM Tuning Torque demand Limits

The above table was set at a desired maximum beyond standard OE settings globally i.e. for every gear and engine speed setpoint. The overall maximum final Indicated torque limitation, "Maximum Torque Final" is set out of the way at 1023 Nm. The output of the Maximum Torque AT/MT table + frictional losses and the ratio of lambda and ignition efficiencies, as summarised to create the indicated torque set point for air mass, is used on an axis of a 3D table to set the Airflow target or Reference Air Charge. There are several of these Airflow tables, based on the position of the port flaps, valve lift, and the camshaft phase shift of inlet and exhaust.

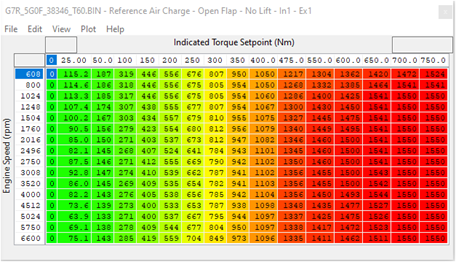

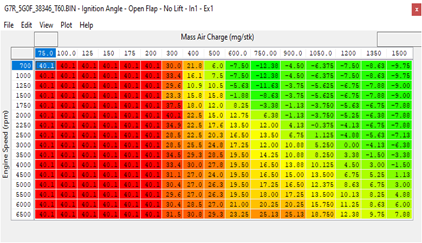

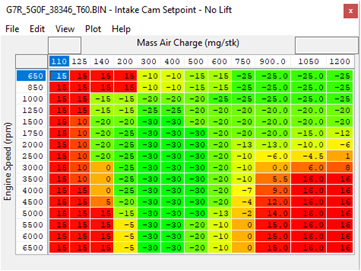

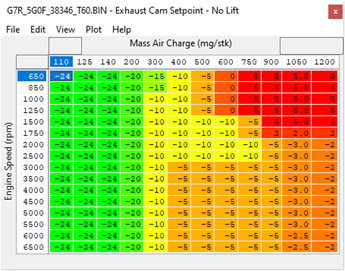

At wide open pedal (WOP) with the intake flaps lowered (open), valve lift and the camshafts at their end stops. The indexing will be - Open flap - No Lift - In1 - Ex1, whereas at light loads, for example at 2500 rpm, the intake flaps will be raised (closed), the exhaust only AVS will be in lift and the camshafts can be in overlap, this will result in a Reference Air Charge table with the index - Closed flap - Lift - In3 or In2 or Ex3 or Ex2 being utilised.

A typical example of Reference Air Charge taken from an example rom of the Ecutek Golf 7 R shown below.

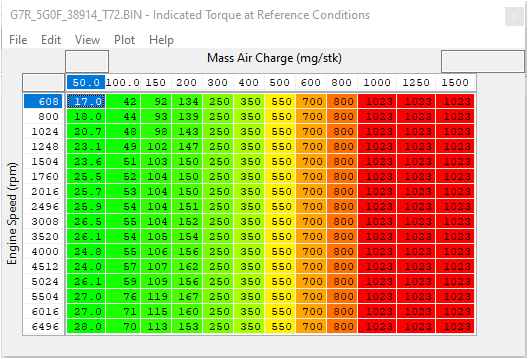

Indicated Torque at Reference Conditions

Logging Item - Torque Actual at Clutch

Should be set to not limit reported engine torque used to calculate clutch pressure in the DSG> This is set up to a maximum at higher airflows.

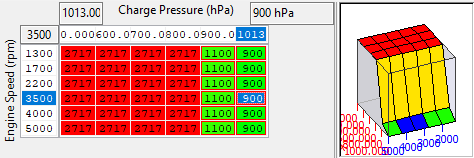

Logging item Air Mass Charge from Manifold, Air Mass Charge Setpoint

With the airflow setpoint determined, the output of the Refence Air Charge table, air mass in mg/stk, is used as an axis for ignition setpoint tables (which will be covered later) and is also converted into intake manifold pressure, used as an axis for determining pressure upstream turbo limits. As mentioned in the previous slide, there are several Reference Air Charge tables which are indexed by active port flaps, valve lift, intake/exhaust cam position.

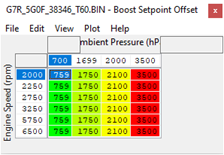

Once the Refence Air charge tables and Maximum torque tables are set high enough to achieve desired pressure upstream of the throttle, the boost setpoint offset table can be calibrated. All boost calculations are derived from the Refence Air charge tables and Maximum torque tables.

Typical Boost pressure offset table shown below derived from Mass Charge from Manifold and Air Mass Charge Setpoint .

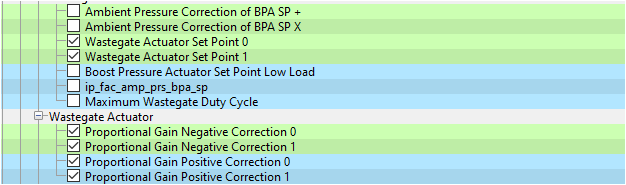

The turbocharger feature on the EA888 as certain sub features modelled to determine turbocharger speed, turbo pressure ratio and the wastegate position for a desired pressure upstream throttle.

To achieve the desired boost beyond standard, the limit for turbine speed must be increased to avoid any limiting errors. WG position tables usually remain as default for calibrations based on standard hardware. For hybrid turbos, errors in desired WG position, causing an under or overboost condition require some tuning of the WG PID and position set point tables to ensure the WG actual position is the same as the setpoint.

With RaceROM version 3 you can now tune the simplified WG target map and OEM PID controls

VW AG EA888 RaceROM Tuning Simplified/Traditional WGDC control

Logging items - Pressure Upstream Throttle, Manifold Absolute Pressure, Wastegate Position, Wastegate Position Setpoint, Exhaust Pressure Flow Factor, Intake Pressure Flow Factor, Turbine Actuator Proportional/Integral, Turbine Actuator Final Value ,Turbo speed/setpoint.

Optimise the Ignition Timing.

With the Airflow and boost settings elevated for more performance, optimisation of ignition setpoint will become necessary to ensure the engine can be operated safely between broadline det (BLD) and maximum brake torque timing (MBT).

The EA888 Simos ECU has two important sets of ignition tables. The basic ignition angle or Ignition Angle and the MBT ignition angle or Ignition Ref Angle.

The Ignition Ref Angle is set during OE development and represents the theoretical maximum ignition setting on a reference high octane fuel, with a lambda efficiency of 1. It shouldn't require much if any alteration on calibrations involving standard hardware. It also takes part in ignition efficiency calculations. The final ignition setpoint will be determined by experimentation in the ignition Angle tables.

There are several Ignition setpoint tables for both Ignition Ref Angle and Ignition Angle, which are indexed by active port flaps, valve lift, intake/exhaust cam position.

At wide open pedal (WOP) with the intake flaps lowered (open), valve lift and the camshafts at their end stops. The indexing will be - Open flap - No Lift - In1 - EX1, whereas at light loads, for example at 2500 rpm, the intake flaps will be raised (closed), the exhaust only AVS will be in lift and the camshafts can be in overlap, this will result in a Reference Air Charge table with the index - Closed flap - Lift - In3 or In2 or Ex3 or Ex2 being utilised

Now with RaceROM version 3 you can tune 4 map switch mode variant's that replace the 9 High and Low lift flap open maps.

VW AG EA888 RaceROM Tuning Ignition-Timing

A typical ignition table for WOP is shared in the illustration below.

Logging items – Ignition 1 to 4

Optimisation of knock correction.

Knock detection and control is usually a feature that is designed during a lengthy OE process involving hours of design validation on an engine dyno, which is then tested on various market place fuels and climates and involving Tier 1 grade combustion analysing equipment.

The knock control feature, allows each cylinder to be optimised by allowing the cylinder to operate safely and as close to MBT as possible and thus maximising torque while reducing the spark spread across the engine cylinders.

This feature also has benefits of reducing engine roughness and improving fuel consumption while delivering the best engine response.

Depending on engine modifications and loads, detection integrals can be optimised as well the step changes to correct for a knock event when running boost levels beyond the factory set point of 2200 mbar.

Tables that will commonly be revised are:

- Knock Detection - integral correctional increase.

- Delay Before Dynamic Knock Speed. Transient knock sensitivity

- Delay Before Timing Increase in Fast Mode

- Knock Retard Increment

- Knock Retard Decrement

Logging Items - Knock Retard 1 to 4

Reviewing ignition compensation tables

- Ignition Angle Base - Correction for all combustion modes.

- Ignition Angle Correction Combustion mode 2 - FSI double injection ignition correction.

- Ignition Angle Intake Temp Corr. - Ignition correction for manifold temperature increase.

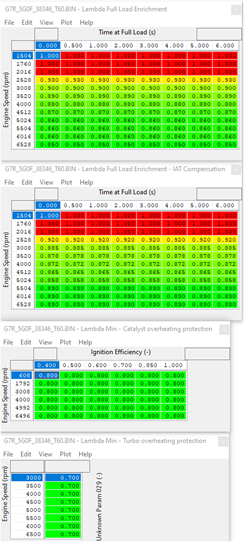

Tuning the Lambda Set Point. (Air Fuel Ratio)

On the EA888 Gen 3 engine, a lambda set point of 1 is targeted for the entire operating range. Featuring a piston design which is profiled to suit direct injectors and an optimised combustion chamber design, lambda 1 is achieved at spark plug, for engines operated at factory load limits.

To achieve optimum power with greater cylinder pressure, a richer lambda set point is recommended. Lambda setpoint can be influenced by high intake or catalyst temperatures, as well as turbo protection tables. So these tables will have to be altered in a safe manner to suit the new fuel target.

Optimum settings between LBT (Lean Best Torque) and RBT (Rich Best Torque) should be determined by experimentation.

Now with RaceROM version 3 there are map switch mode dependent targets

VW AG EA888 RaceROM Tuning - RaceROM-Lambda-Setpoint

Logging items - Lambda Actual, Lambda Target

Setting The Ideal Camshafts Transitions and Valve Lift.

The factory camshaft phase shift can be further optimised to increase cylinder fill.

This is with lift or without.

An experiment involving setting individual cam tables i.e. the exhaust bank or the intake bank at a time, to global settings at high air flow set points and all engine speed set points, can be used to find the best setpoint at various engine speed break points.

The results of the experiment can be blended into the cam set point tables for the best full load curve.

Logging items - Intake Cam Absolute Position, Intake Cam Absolute Position Setpoint, Exhaust Cam Absolute Position, Exhaust Cam Absolute Position Setpoint

Valve lift is usually zero at high airflows. Testing with larger turbos have seen benefits in cylinder fill at switch off threshold greater than 3600 rpm.

Logging Item - Valve Lift Setpoint.

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

Retail customers ** If you have any doubt that you do NOT have the experience required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner use it for you ** |