BMW ProECU Tuning Guide: N55 & S55

Introduction

The ProECU for BMW F-Series products cover N55 and S55 platforms across a range of models. Providing an all-in-one tuning solution that enables a tuner to properly calibrate cars of all hardware levels.

Introduction

The ProECU for BMW F-Series products cover N55 and S55 platforms across a range of models. Providing an all-in-one tuning solution that enables a tuner to properly calibrate cars of all hardware levels.

RaceROM custom code by EcuTek adds functionality unique in the tuning marketplace such as CANbus sensor input, Flexfuel and Custom Maps for general purpose use.

The strategies in the BMW F-Series ECU are many and complex, fortunately tuning can begin at a very basic level by simply increase the requested torque and lifting some safety limits. As hardware upgrades become more thorough and power requirements increase, more in-depth calibration is required.

| Note |

|---|

maps denoted with a RaceRom logo are tables from the RaceRom software and require the addition of that software. |

Supplemental Content

Platform Specific

| Child pages (Children Display) | ||||

|---|---|---|---|---|

|

General

| Panel | ||||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

|

Engine Variants

| Panel | ||

|---|---|---|

| ||

|

| Panel | ||

|---|---|---|

| ||

|

| Panel | ||

|---|---|---|

| ||

|

| Panel | ||

|---|---|---|

| ||

|

Boost Control

For the most part, boost control is adjusted in response to the torque demand, as torque demand increases, the computer will modulate the boost level requested to match the torque level needed.

| Column |

|---|

Maps |

| Column |

|---|

|

| Column |

|---|

Live Data Parameters |

Bst. FF Disable PR Threshold

This map functions as a threshold for switching between two different boost control methods. When the PR (Power Rate) is below the value in the map, the Turbo Power Model based control is used. When it's above this map it utilises direct wastegate duty based control.

This is typically the first map you'll want to tweak, we suggest values similar to what we have used in the M2 ROM pictured.

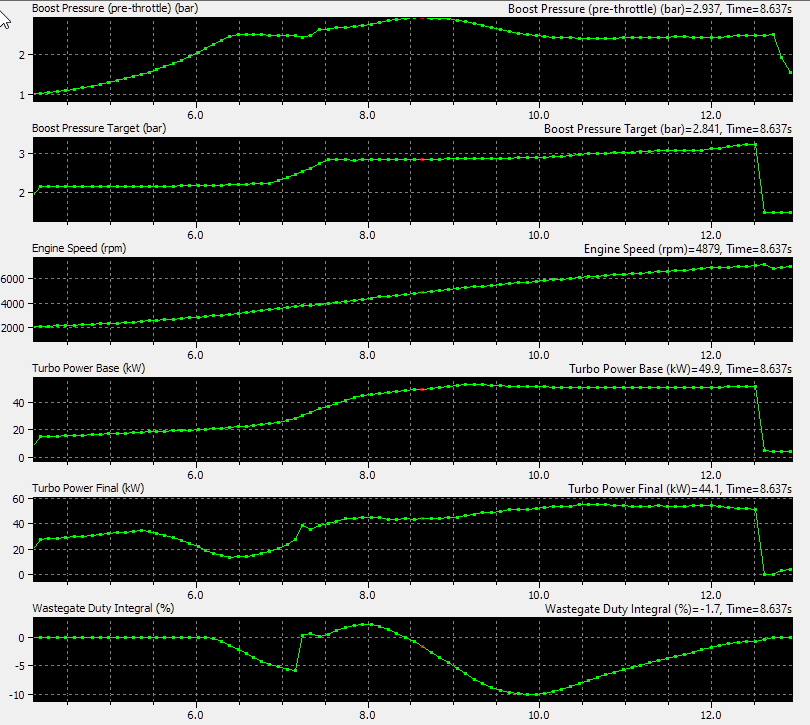

In the log shown below we cover an overboost and underboost condition.In this particular case, the underboost is being caused because the Turbo PR limits are capping the boost target. It's quite easy to spot when comparing the Boost Target against Actual Boost +Boost Error (As demonstrated by the "Boost Target Real" parameter shown below.

Looking at the same overboost example before, we can see there's quite a large amount of overboost.

The overboosting begins around 850 kg/h Mass Air Flow and ends just short of 1050kg/h at 2.1 to 2.3 Turbo Pressure Ratio.

With that information in hand, we'll take a look at the Compressor Power Base cells controlling behavior at those points.To give us an idea of the rough corrections needed, we can reference the log file again and compre the Turbo Power Final and Turbo Power Base

Camshaft Timing

Fuelling

Boost Control

For the most part, boost control is adjusted in response to the torque demand, as torque demand increases, the computer will modulate the boost level requested to match the torque level needed. In this form, while it's complex in the way it's implemented, it has the ability to be relatively easy to tune.

Target pressures for the inlet manifold and resulting boost are more difficult to control beyond what the ECU calculates as being appropriate, but with careful tuning it's possible to achieve almost anything. The boost target begins with Torque request, which is used to calculate the correct pressure to achieve the desired torque in the current conditions.

Wastegate actuator control is achieved with a system using two control methods, one based on the turbo shaft power, and another that makes further corrections to the target wastegate position. It's reasonable to tune both systems to keep the boost on the target.

Bst. FF Disable PR Threshold

This map functions as a threshold for switching between two different boost control methods. When the PR (Power Rate) is below the value in the map, the Turbo Power Model based control is used. When it's above this map it utilises direct wastegate duty based control.

This is typically the first map you'll want to tweak, we suggest values similar to what we have used in the M2 ROM pictured.

In the log shown below we cover an overboost and underboost condition.

In this particular case, the underboost is being caused because the Turbo PR limits are capping the boost target. It's quite easy to spot when comparing the Boost Target against Actual Boost +Boost Error (As demonstrated by the "Boost Target Real" parameter shown below.

Looking at the same overboost example before, we can see there's quite a large amount of overboost.

The overboosting begins around 850 kg/h Mass Air Flow and ends just short of 1050kg/h at 2.1 to 2.3 Turbo Pressure Ratio.

With that information in hand, we'll take a look at the Compressor Power Base cells controlling behavior at those points.

To give us an idea of the rough corrections needed, we can reference the log file again and compre the Turbo Power Final and Turbo Power Base

Fueling

The F-Series fuel system is based around the Bosch HDP5 range of components comprising of:

- Low Pressure in tank pump with closed loop pressure control

- High Pressure pump with dedicated drive cam

- High pressure HDEV5.2 Injectors with CVO adaption.

It's possible to upgrade elements of the system, and many N55 cars will require at least an upgrade high pressure pump to take full advantage of even the stock hardware.

Typically the stock fuel pressure maps are only calibrated to deliver 20MPa. While you can change fuel target even a bump to 26-27MPa results in only around 23MPa. In addition it ends up slowly ramping up to that target if you only rely on the closed loop control in order to achieve your desired fuel pressure target.

The right way to raise your fuel pressure is to start off by adjusting the fuel pressure targets, then the HPP Feedforward Angle Offset & HPP Feedforward Angle Slope maps in order to correctly deliver the target.

| Column |

|---|

Maps |

| Column |

|---|

|

| Warning |

|---|

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

Retail customers ** If you have any doubt that you do NOT have the experienced experience required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner to use it for you ** |

| Panel | |||||||

|---|---|---|---|---|---|---|---|

| |||||||

|