VW AG EA888 Engine Tuning

Introduction

The EA888 Gen 3 (EA888.3) is a global engine suitable for MLB (Modularer Langsbaukasten/Longitudinal ) and MQB (Modularer Querbaukasten/Transverse) platforms, capable of meeting the latest emission and fuel economy targets in different markets

In the Europe, the new MQB EA888 Gen 3 engines were introduced to Volkswagen Golf, Skoda Octavia, Seat Leon and Audi A3/S3 vehicle.

A Simos 18 Engine Control unit was utilised in order to control the features of the engine. The Engine family has two different sizes currently (1.8 litres and 2.0 litres) with the larger (2.0l) family offering both a lower output (but high compression) option and a high output (Lower compression) option.

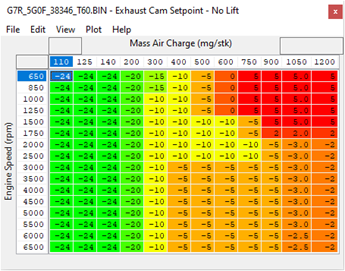

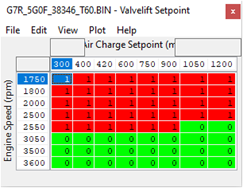

Currently Gen 3 EA888 engines, used in MQB cars covered in this document, use an exhaust only AVS (Audi Valvelift System).

Supplemental Content

Platform Specific

General

Table of Contents

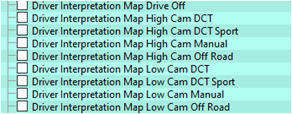

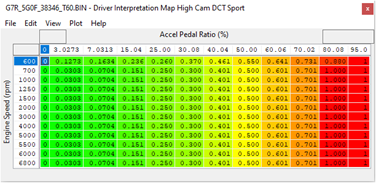

- Accelerator pedal maps

The ECU maps that relate pedal opening percentage and throttle butterfly valve angle. - ACT (Air Charge Temperature)

Also written as AIT (Air Intake Temperature) or CAT (Charge Air Temperature). - Active Regeneration

Diesel particulate filter clearing, which is carried out when required by the engine management system, which raises exhaust temperature by temporarily introducing a particular mode of engine operation. - Advance Multiplier

The degree of ignition timing advance between the ignition base map and the maximum ignition timing, which is limited either by a secondary 'max' map or an additional advance map. - AFM (AirFlow Meter)

Continuously measures the flow of engine intake air. - AFR (Air Fuel Ratio)

The ratio of intake air to injected fuel. 14.7:1 is the ideal 'stoichiometric' ratio, which means the ideal ratio at which all oxygen is consumed and all fuel is burned. - AT

Automatic Transmission - AIT (Air Intake Temperature)

Also sometimes written as CAT (Charge Air Temperature) - APS

Accelerator Pedal Position - ASC (Adaptive Shift Control)

Nissan's 'learning' auto-transmission control, which adapts shifting style to the driver's preferences and road conditions. - Auto blip

The management system's brief burst of engine revs to allow the driver to downshift under braking. - AVS

Audi Valve lift System - BLD

Border line Detonation - CAF (Calculated AirFlow)

Where the airflow sensor voltage does not have a linear relationship to the flow, the ECU uses a scaling map to translate sensor voltage into an airflow rate value. - CAN/CANbus (Controller Area Network)

A vehicle bus standard that allows microcontrollers and devices to communicate with each other in applications without a host computer. Originally designed for multiplexing vehicle electrical wiring. - CAT (Charge Air Temperature)

Sometimes also written as ACT (Air Charge Temperature) or AIT (Air Intake Temperature) and not to be confused with Cat - an abbreviation for catalytic converter. - CEL

Check Engine Light - Closed Loop

Control based on feedback, or input responding to output. A feedback control loop is used in three-way catalytic converter systems and various electronic circuits. - Colour by Lambda

EcuTek software feature that provides an easy, live visual representation of fuel/air mixture changes. - Colour by Knock

EcuTek software feature that provides an easy, live visual representation of cylinder knock characteristics.

Custom Datalogging

Allows the logging of 50 or more custom parameters not available from the factory ECU - Custom Gauge (see also Gauge Hijack)

This allows the tuner to display a fixed value or the output of a custom map on the dashboard gauges, the exact functionality depending on the type of gauge cluster fitted to the car. It can be used, for example, to display the required fuel octane for each map switch mode, to display the current AFR or the output of an external ethanol content sensor - Custom Maps

Bespoke new maps added by Ecutek for increased functionality - CVN (Checksum Verification Number)

A checksum is a small datum from a block of digital data, whose purpose is to detect errors that may have been introduced during its transmission or storage. Usually applied to an installation file after it is received via a download - DBW (Drive By Wire)

The use of electrical or electromechanical systems for performing vehicle functions traditionally achieved by mechanical linkages - DCT

Dual Clutch Transmission - DeltaDash

An early EcuTek software data logger for Subaru cars, whose functionality is now incorporated in the ProECU product - DI (Direct Injection or Direct Injector)

The favoured petrol engine technology in which fuel is injected into the combustion chamber rather than the inlet port - DLC

Diagnostic data Link Connector - Dongle

A small hardware device (such as the ProECU Licence Key USB dongle) which connects to another device, typically a computer, to provide it with added functionality, copyright protection or product licensing - DPF (Diesel Particulate Filter)

A carbon-particle (soot) trap in the exhaust system of a diesel

DTC (Diagnostic Trouble Code)

A trouble/fault code generated and stored by the engine management when it detects a problem - DSG

Direct Shift Gearbox - DTC

Diagnostic Trouble Code, also referred to as CEL codes (check engine light) - DQ

Transverse Mounted DSG Gearbox - ECO

Economy - ECT

Engine Coolant Temperature - ECU

Engine Control Unit. The computer for the powertrain of the vehicle. Also called PCM, ECM, PCU etc. from various manufacturers - EGR

Exhaust Gas Recirculation - EGT

Exhaust Gas Temperature - Engine Load

AirFlow divided by engine RPM; effectively how much air enters the engine per revolution. It may be expressed as a percentage of cylinder fill - EOI (End of Injection)

Stipulated as an angle, in degrees - ESP (Electronic Stability Program)

Also Dynamic Stability Control, is onboard computer technology that improves vehicle stability by detecting loss of traction or steering control and intervening to correct it via the antilock braking system and engine control - Equivalence Ratio

The desired closed-loop AFR that the management ECU attempts to meet - EX

Exhaust - Fail Safe

A device or function attribute that, in the event of a specific type of failure, responds in a way that minimises or negates harm to other devices or persons - FastFlash

EcuTek's rapid system of ROM programming by block, where all code is built into the ECU - FI (Forced Induction)

Boosted air charge, as with supercharging and turbocharging - Flash Licence (EcuTek)

See 'Dongle' previously - FFS (Flat-Foot Shifting)

An EcuTek ProECU feature that lets you keep your foot flat on the accelerator while changing gear so as to minimise change time and keep up engine speed and torque, maximising acceleration in the next gear up - FlexFuel (Also Dual Fuel)

Refers to an engine that runs on more than one fuel (eg petrol and ethanol) and both fuels share the same fuel tank - FMIC

Front Mounted Intercooler - Forced Induction

Utilizing a supercharger or turbocharger to force air into the intake tract of a vehicle. See NA / Naturally Aspirated - FPW (Fuel Pulse Width)

The duration of opening of each injector in milliseconds (ms) - FT (Fuel Trim)

A system-integrated ability to automatically make small adjustments to fuel metering to compensate for certain factors affecting engine operation - FTLT (Fuel Trim Long Term)

Fuelling compensation applied on long-term basis - FTST (Fuel Trim Short Term)

Fuelling compensation applied on short-term basis - Gauge Hijack (see also Custom Gauge)

The temporary reassignment of certain dashboard instruments via EcuTek software in order to display other functions such as AFR, Boost, Fuel Trims or Map Switch modes - Hybrid Speed Density

A programmable function that allows switching between MAP and MAF airflow sensing for the Engine Load calculation depending on operating conditions - Hysteresis

A slight margin for variation, or 'cushion zone', particularly with reference to a predetermined rev limit - Idle Learning

A program feature that balances idling parameters - particularly on a dual-intake system such as that of the Nissan GT-R - IMRC (Intake Manifold Runner Control)

Or Intake Manifold Swirl Control (IMSC), a vacuum and solenoid-actuated system that partially closes an intake duct to generate intake air turbulence under low-power running - IMSC (Intake Manifold Swirl Control)

Or Intake Manifold Runner Control (IMRC), a vacuum and solenoid-actuated system that partially closes an intake duct to generate intake air turbulence under low-power running - IN

Intake - Injector Scaling

The recalibration of fuel injector characteristics (parameters such as flow rate, pulse width etc) to suit engine modifications - ISS (Intercooler Spray System)

A coolant-spraying mechanism that maximises intercooler efficiency and is used on a few high-performance turbocharged cars - K-Factor

A Nissan-specific multiplier for the manufacturer's base fuel schedule - a figure best left unchanged - K-Line

A pre-CANbus communications data-transmission line and protocol still occasionally used in conjunction with a CANbus - Knock Correction

The amount of ignition timing correction (positive or negative) set by the ECU in response to cylinder knock, or its absence - Knock Retard

The amount of ignition timing retardation set by the ECU in response to detected cylinder knock - Lambda Sensor (O2 Sensor)

A sensor in a petrol-engine exhaust system that continuously measures the concentration of oxygen in the exhaust gases - Launch Control

An electronic aid - effected via a number of management functions - that assists drivers of both racing and street cars to accelerate cleanly (ie with minimal wheelspin) from a standing start - LBT

Lean Best Torque - Limp-Home

A reduced-performance mode of engine operation adopted by the management system when certain engine faults are detected - Live Data

Data streamed from the management ECU as the engine is running - MAF (Mass Air Flow)

As in MAF Sensor; the amount of air flowing is stipulated in grammes per second (g/s) - MAF Bank Switching

A feature that allows airflow measurement correction after the fitting of an aftermarket intercooler that swaps airflow between cylinder banks - MAP (Manifold Absolute Pressure)

As in MAP sensor, whose output is stipulated in psi or bar - Map Switching

The selection of an alternative engine management map via a 'hijacked' or 're-purposed' control in the car - Master Tuner (Ecutek)

Master Tuners are the most experienced category of engine tuners (as determined by EcuTek) and have the authority to purchase ProECU Programming Kits and retail them to vehicle owners together with their own ECU calibrations - MBT (Maximum Best Torque/Minimum Best Timing/Maximum Brake Torque)

Can also be understood as 'minimum timing advance for best torque' - MQB

Modularer Querbaukasten (Modular Transverse Platform used by VAG in such vehicles as the GTI, Audi A3) - MLB

Modularer Langsbaukasten (Modular Longitudinal Platform used by VAG in such vehicles as the Audi A4, A5) - MRP (Manifold Relative Pressure)

Negative or positive inlet manifold pressure relative to atmospheric pressure - MPI

Manifold Port Injection or Multi-Port Injection - MT

Manual Transmission - NA (Naturally Aspirated) Also refferred to as NASP

Unboosted, neither turbocharged nor supercharged - Nm (Newton Metre)

A metric unit of measurement for torque. 1 Nm ≈ 0.73756215 lbft

- OBD (On Board Diagnostics)

A general term for a vehicle's self-diagnostic and reporting capabilities; OBD systems give access to the status of the various vehicle sub-systems - OBD-II (On Board Diagnostics)

The current OBD standard capable of providing real-time data and a standardised series of diagnostic trouble codes. - OEM (Original Equipment Manufacturer)

Most often used by EcuTek in the context of the manufacturer of the car being modified, and specifically its 'OEM' (factory) engine management maps - Open Loop Control

A control mechanism that does not observe the output of the process it controls, but instead computes its input on the basis of current state and its integral model - Per-Gear Rev Limit

As the name suggests, different rev limits can be set for individual gears - PI (Port Injection or Port Injector)

Fuel injection into the air inlet port rather than the combustion chamber - as with Direct Injection - Piggybacking

An undesirable method of tuning whereby various factory-standard engine-management ECU input and output signals are 'hijacked' or manipulated by a third-party device in order to 'deceive' the ECU - Power Balance

The disabling of individual fuel injectors to help pinpoint cylinder faults - ProECU TOOLS (EcuTek)

Everything the EcuTek Tuner needs - hardware, software, licence key and documentation - to successfully tune using ProECU - ProECU Programming Kit (EcuTek)

The hardware and software that Master Tuners purchase from EcuTek and sell on to retail customers for their own, non-commercial use, together with the relevant vehicle ROM files. - ProECU Tuning Suite (EcuTek)

The vehicle-specific software needed to produce tuned ROM files. Tuning Suites are ‘trade only’ tools that allow ECU calibrations to be altered (for a wide range of tuning requirements) then programmed into the factory ECU using the ProECU Programming Kit - RaceROM Features (EcuTek)

Additional and enhanced features for OEM vehicle ECUs tuned with EcuTek tuning tools, which bring increased tuning and driving capabilities such as Map Switching, Flat-Foot Shifting, Valet Mode and more. RaceROM features are included in the cost of the relevant Tuning Suite - RaceROM Feature File (EcuTek)

The EcuTek code and data applied to an ECU ROM file before it is programmed into a vehicle ECU - RAM (Random Access Memory)

A type of computer data storage (usually volatile as it needs constant power) in integrated circuit form that allows data to be read or written in almost the same amount of time regardless of its physical location within the memory - RBT

Rich Best Torque - Regional Distributor (EcuTek)

A company appointed by EcuTek to exclusively sell and support EcuTek products in a specific country or defined territory; receives support directly from EcuTek - Regional Sub-Dealer (EcuTek)

Receives support from the EcuTek Regional Tuner chosen to be their 'parent' tuner who provides ROM file calibrations and tuning support, plus any EcuTek software required - Regional Tuner (EcuTek)

Operating in the specific country or defined territory of the Regional Distributor, the Regional Tuner purchases software, hardware and Flash Licences from, and is supported by, that distributor - Rolling Cylinder Cut

The engine management-controlled shutting-off of one or more cylinders in a predetermined sequence to achieve smoother rev limitation - especially in conjunction with Launch Control - Roll Racing

In motor sport a moving (rather than standing) start to a race that reduces shock stresses on vehicle components; also an EcuTek RaceROM feature for the Nissan GTR - ROM (Read Only Memory)

A type of non-volatile memory used in computers and other electronic devices in which stored data can be modified only slowly, with difficulty or even not at all - RRBC

RaceROM Boost Control - RRFF

see RaceROM Feature File - SC

Supercharger or Supercharging - Soot Accumulation Ratio

The pressure differential across two points in a diesel particulate filter that determines pressure drop, and therefore the need for regeneration (clearing) of the filter - Speed Density (SD)

The calculation of engine load from manifold absolute pressure rather than mass air flow - SDI

Suction Direct Injection - SD-VE (Speed Density-Volumetric Efficiency based)

The SD feature changes the way Mass Airflow is calculated: in SD mode the ECU disregards MAF sensor input and calculates Mass Airflow based on Engine Speed, Manifold Pressure and Air Temperature - Single Turbo

A system utilizing a single exhaust driven turbocharger for an entire engine system. - Stoichiometric

The ideal air/fuel mixture ratio (of 14.7:1) to give complete combustion - Sub-Dealer (EcuTek)

A member of the EcuTek Tuner network who tunes customer vehicles using ProECU Tools and suitable tuned ROMs provided by a 'parent' EcuTek Tuner. There are two Sub-Dealer types: those who program only and those who create and edit ROMs using full Edit Software acquired from a parent dealer - SRM (SynchroRev Match)

A Nissan name for programmed double-declutching-style throttle 'blips' on gearbox downshifts – otherwise known as Autoblip in EcuTek-speak - TC

Turbocharger or Turbocharging - TCM

Transmission Control Module - TCS

Traction Control System - Throttle Angle

The opening angle of the throttle butterfly valve, in degrees - Throttle Target Max

The maximum allowed throttle valve opening angle in relation to RPM - Torque Actual

The current torque produced by the engine, as calculated from MAF; the amount of torque available irrespective of Torque Demand - Torque Demand

The torque demanded by the driver using the accelerator pedal; the driver input - Torque Monitoring

The calculation of torque output from predetermined engine management data when there is no direct means of measuring it (ie with a dynamometer) - Trustful Checks

Pre-programmed data checks and comparisons built into some ECUs to detect and safeguard against errors, particularly those with road-safety implications - Tuner (EcuTek)

A business whose facilities and experience are deemed suitable by EcuTek to recalibrate engines with a ProECU Programming Kit and Tuning Suites, and which receives support directly from EcuTek - Tuning Bundle (EcuTek)

EcuTek multi-pack of tuning suites available from the EcuTek web store at a preferential price. - Tuning Suite (EcuTek)

The EcuTek software required to tune a given car - Twin Turbo

A system utilizing two turbochargers for a single engine system. Twin-turbo setups can fall into the two basic categories or parallel operation and series (sequential) operation - USB

Universal Serial Bus - Valet Mode

An easily enabled low-power mode with torque, speed and distance settings that brings peace of mind when entrusting your vehicle to another person - VDC (Vehicle Dynamics Control)

A system based on anti-lock braking that senses a vehicle's loss of grip and impending wayward handling and applies individual brakes and adjusts engine power in order to correct it - VE (Volumetric Efficiency)

The efficiency with which intake air is packed into the cylinders, expressed as a percentage - the higher the better - VTC (Variable Timing Control)

Adjusts the inlet and/or exhaust camshaft position relative to the current crankshaft position - VTEC (Variable Valve Timing and Lift Electronic Control)

A Honda system that improves petrol-engine volumetric efficiency by using two camshaft profiles, selecting between them by hydraulic means. Not to be confused with VVT - VVEL (Variable Valve Event and Lift)

Nissan's petrol-engine valve-lift control system uses links varied by stepper motor to open intake valves, which allows continuous adjustment and optimisation of valve lift. Not to be confused with VTEC - VVL (Variable Valve Lift)

- VVT (Variable Valve Timing)

Advances or retards the inlet or exhaust camshaft position relative to the current crankshaft position without changing either cam profile or valve lift - VVT-i (Variable Valve Timing with Intelligence)

Toyota's petrol-engine variable-timing technology for inlet valves, featuring two-stage cam phasing under hydraulic control. Variants such as VVTL-i, Dual VVT-i, VVT-iE and Valvematic have since followed - Wastegate Duty (also called WGDC Wastegate Duty Cycle)

The programmed cycling of a solenoid valve that applies positive pressure to the turbocharger wastegate actuator rod in order to control turbo speed - WG (Wastegate)

The boost-limiting valve of a turbocharger installation - WHP (Wheel HorsePower)

The horsepower produced and measured at the driven wheels - WOP

Wide Open Pedal (100% accelerator pedal position) - WOT

Wide Open Throttle, throttle in the fully open position - WTQ (Wheel Torque)

The torque produced and measured at the driven wheels

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

If you do not fully understand this product then you WILL damage your engine, ECU or your vehicle.

Please ensure you fully read all EcuTek manuals BEFORE attempting to use ProECU with your laptop or your vehicle.

Use with extreme caution and understanding at all times, if in doubt then do not proceed.

EcuTek accepts no responsibility for any damage to the engine, ECU or any part of the vehicle that results directly or indirectly from using the product.

** If you are in any doubt that you do NOT have the experience required to use this product then you should NOT USE IT **

Retail customers

** If you have any doubt that you do NOT have the experience required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner use it for you **