Mitsubishi Diesel Tuning Guide

Brandyn Mowat

Summary of Software

ProECU software has been introduced to allow reprogramming of the factory ECU in order to tune the necessary components of the calibration in order to allow for modifications and increases in power. This is not a standalone repalcement ECU so you shouldn't run into the associated issues or disadvantages of setting up a purpose-built ECU and control system from scratch.

The software allows easy control over most factory parameters including:

- Boost Targets and wastegate control

- Target AFR

- Ignition Timing

- Fuel Delivery including fuel pump calibration (using the same style pump as OEM)

- Airflow Measurement and fuel compensation

General Diesel Tuning Information

Airflow

Increasing Power and Torque output with more fuel (Injection Quantity mm3) does not actually increase airflow, as seen with petrol engines where airflow can be related to power output. Diesel engines run continuously with a large excess air ratio.

Diesel AFR targets

Wideband Lambda sensors should be used for measuring Air Fuel Ratio in the exhaust pipe, similar to petrol cars.

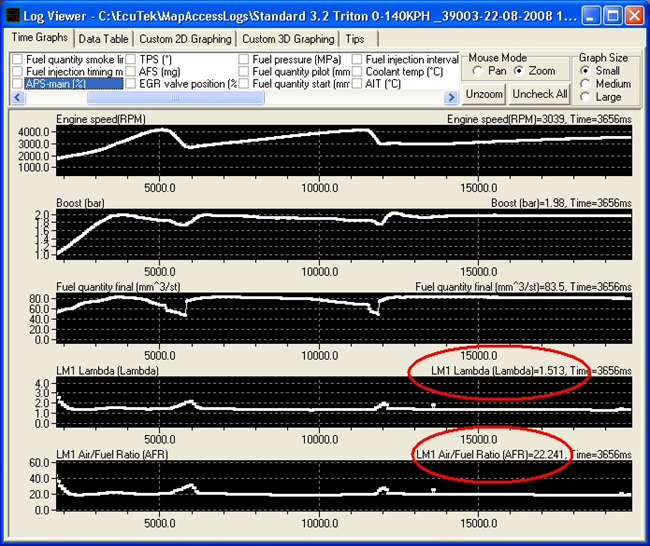

The Lambda and AFR readings shown below were measured using the Innovate LM1 (or LC1). The Innovate sensors can be imported into FlashCAN in order to view and log the true AFR or Lambda readings. The logged readings and then be viewed in DeltaDash.

Exhaust Gas Analysis, in our opinion, is easier to comprehend as a Lambda value that as an AFR value. For example: 1.3 or 1.8 Lambda is easier to understand than 19:1 AFR or 26:1 AFR.

Turbo Diesel Engines running without a Throttle Butterfly restricting the air intake from the turbocharger will run a minimum of 100KPA (1 Bar) Absolute even at Idle. It is rare to see vacuum in the Inlet Manifold unless in certain conditions where the throttle butterfly is closed by the ECU to create a manifold depression for either EGR control or maybe Brake Servo assistance.

As soon as Engine RPM increases and Turbo speed increases the AFR can be anything up to Lambda 2.0 or even higher. Expect to see a Lambda of around 1.6 to 1.9 on normal part throttle driving and down to a Lambda of 1.3 on full load conditions.

Anything below Lambda 1.1 and you will start to see the dreaded Black Smoke.

On models without Electronic Boost Control it is possible to increase the boost manually by shortening the Wastegate actuator rod or by using a bleed off between the compressor feed pipe and the Wastegate actuator.

Increasing the boost by 0.2 to 0.3 Bar is normally sufficient to raise the Lambda value and reduce the Black Smoke. Don’t forget to increase the Boost Limit proportionally with the higher boost pressure.

EGT should ideally be measured pre-turbo as with petrol cars, as diesel cars can suffer from high EGT if too much fuel is added. Take care and make modest increases if you are not measuring EGT.

EGR (Exhaust Gas Recirculation)

EGR is used to reduce NOx emissions at light load conditions. Basically EGR allow spent exhaust gas back into the Intake to ‘dilute’ the incoming fresh charge of oxygen. This reduces cylinder pressure which reduces cylinder combustion temperatures which in turn means lower NOx output, but this polluted Intake charge mixed with spent exhaust gas will reduce power output and therefore increase fuel consumption.

From FlashCAN Live Data feature you will see EGR working at Idle and Light Load conditions. Reducing the EGR reduction amount should improve power and more importantly improve fuel consumption.

For a given RPM and throttle angle or torque output there is a target Mass Airflow value in Milligrams of Air from the AFM.

The ECU will then use the EGR valve to try and reach its target EGR Dilution level whilst trying to maintain the Target Intake Airflow in Milligram by monitoring the AFM reading.

Table of Contents

Tuning Tips

Quick Safe Tune

We suggest that you simply increase the Max Injection Quantity maps by percentage.

Very good, easy and simple results can be achieved by adding 15% to actual Injection amount from 1200rpm to 5000rpm over 20Nm of Torque Input. This simple modification will produce a good increase without altering any other maps at all. Further improvement can be made by holding the desired peak torque and extending the desired torque value up to 4000rpm.

Watch your Lambda readings though, as the standard turbo cannot supply enough air past 3400rpm to keep the black smoke from appearing!

Which ROM File to choose

When in Utility Mode you are shown what exact ROM is currently in the ECU. You are also shown a list of compatible ROM files, as shown below:

1860a702_03 - 3.2 DiD Shogun AT EU - DPF

1860a702_04 - 3.2 DiD Shogun AT EU - DPF

1860a702_06 - 3.2 DiD Shogun AT EU - DPF

1860a702_07 - 3.2 DiD Shogun AT EU - DPF

1860a702_08 - 3.2 DiD Shogun AT EU - DPF

Choose the latest revision available, they are normally sequential.

In the case shown above, the latest revision is 1860a702_08.

This _08 revision fixed various CEL conditions and also includes improvements for Engine Knock and phantom DPF errors.

Auto Gearbox Gear change issues

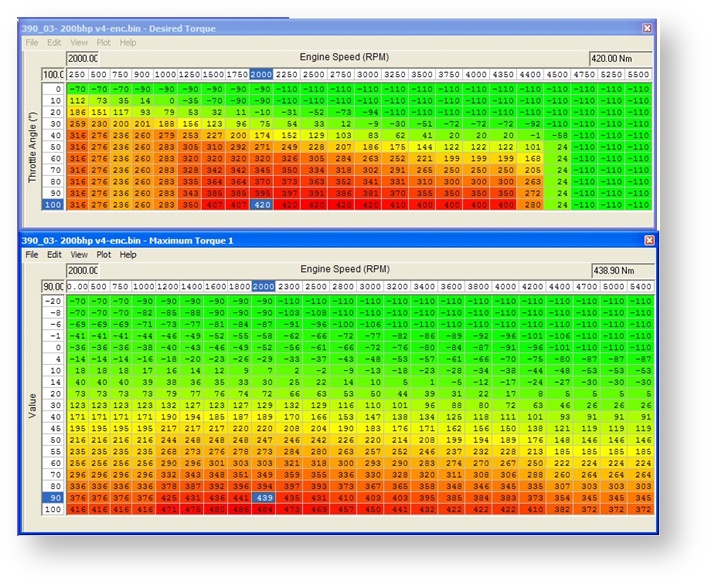

If during tuning an Auto Gearbox model you find the Engine does not change gear quick enough and sits around the maximum engine revs for too long before changing gear, then you will need to change the DESIRED TORQUE or MAXIMUM TORQUE maps at higher RPM especially.

The Engine ECU supplies a current ENGINE TORQUE figure to the gearbox ECU in Nm.

The gearbox ECU uses this current Engine Torque figure to change gear at the correct time.

If you have increased the Injection Quantity mm3 by 20% then this ENGINE TORQUE value will actually be incorrect.

The gearbox will receive a Torque Value of say 300Nm, but actual Torque Output maybe 360Nm. This can cause the Torque Converter to excessively slip between gear changes and lock up.

If on hard acceleration the Engine RPM holds at 4000RPM for too long then try increasing the actual Desired Torque and Torque Limit Values so they are nearer the actual torque output of the Engine. The Gearbox will then see a more realistic ENGINE TORQUE OUTPUT and gearbox control will be tighter and more positive on gear change.

Tuning Guide

Fuelling

Fuel Rail Pressure (MPa)

New Common Rail Diesel Engines use very high fuel pressure. Maximum Rail Pressure used is 180 MPa. There is a Mechanical Pressure relief valve on fuel rail used for safety, which is usually around 200MPa and will bleed fuel back to the tank should Fuel Pressure Increase above this. So do not demand over 200MPa or the Fuel Pump will be working very hard only for the fuel to be wasted back to the tank. Try to avoid increasing Fuel Pressure over the stock 180MPa. It is possible to achieve very good power and torque increases throughout the RPM range without having to change the Fuel Pressure maps.

Should you Increase the Target Fuel Pressure values below 180MPa, ensure these changes are applied to ALL Fuel Pressure Target tables.

A higher Fuel Pressure is a good and proven way of increasing power/torque output across the RPM range and Fuel Atomisation should (in theory) also be improved.

Max Injection Quantity

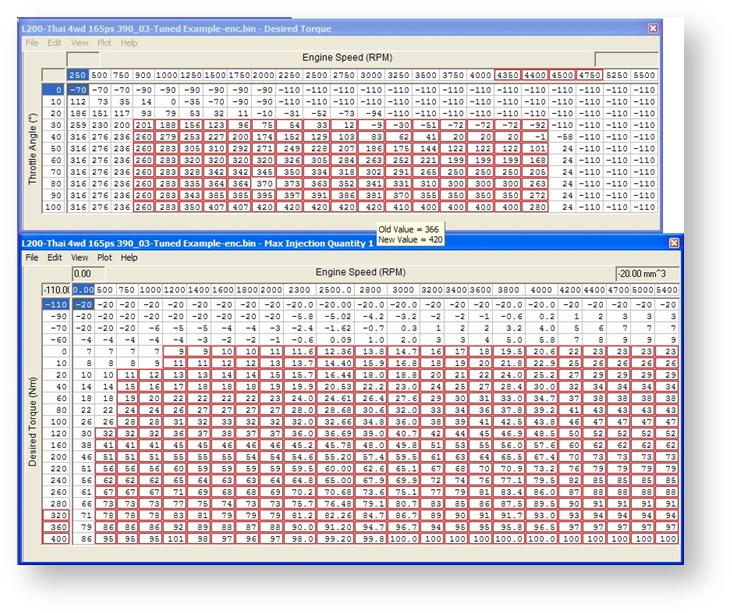

The output torque value from the MAXIMUM TORQUE limit maps is used in the Desired Torque value on the Y-axis of the MAX INJECTION QUANTITY map.

Be sure that you rescale the Y-axis to match nearer to your Desired Torque value.

Example: You can DESIRE 420NM but if the Y-axis on Max Injection Quantity map is only scaled to 360NM then you will not have any more fuel quantity injected between 360NM and 420NM. By extending the Desired Torque values on the Max Injection Quantity map’s Y-axis we will now inject more Fuel Quantity between 360NM and 400NM (in the example shown below). We suggest that you simply increase the Max Injection Quantity map by percentage. Very good, easy and simple results can be achieved by adding 20% to actual Injection amount from 1200rpm to 5000rpm over 20NM of Torque Input. This simple modification will produce a good increase without altering any other maps at all.

Injector Opening Time

This map is a favourite map for most diesel tuners. The ECU calculates how much Fuel

Quantity in mm3 is required and for a given Fuel Pressure how long to keep the Injector open

(Injector Open Time in m/s) to delivery that Quantity of fuel in mm3. Simply Increasing the Opening Time in m/s by a percentage can work reasonably well. One downside (depending on your sales tactics) is any Fuel Consumption meter can become inaccurate due to the ECU not actually Injecting the Quantity of Fuel it actually calculated it injected! The fuel meter will show improved fuel consumption, though this would not actually be true.

Any DPF calculations for regeneration time periods could also be incorrect if based against actual Injection Quantity though this is unlikely to cause a problem as the pressure sensors in the exhaust should trigger a premature regen cycle anyway.

We suggest that you apply a percentage increase to the Max Injection Quantity maps instead.

Smoke Limit

Smoke Limit table will limit the Maximum Injection Quantity amount during transient throttle conditions where the Lambda value will drop and cause Black Smoke. This happens particularly during turbo spool (Turbo Lag), so the Injection Quantity is restrained by the Smoke Limit tables against Boost Pressure. The Smoke Limit Tables will not limit Injection Quantity once the turbo has spooled and is on full boost pressure.

Injection Start Angle

This is the crankshaft angle (normally before TDC) where the Injection process will begin.

If Injection Quantity is increased, then it will take a longer time (m/s) to actually inject this higher fuel quantity (mm3) .

So starting the Injection cycle earlier can reduce chances of Blake Smoke and also Increase Torque Output, but take care for Engine Knock (Diesel Knock). It is suggested that these maps are adjusted with caution and proven on a dyno, as Airflow g/s does not show improvements in power out. We have yet to see an improvement from modifying these maps, so please let us know if you find any good gains!

Fuel Quantity Pilot and Interval Pilot

These maps require expertise to be adjusted correctly. Study various different ROM revisions to see how the manufacture adjusts these maps to adjust for engine noise (Diesel Knock) at light load conditions. The Pilot Injection phase should also reduce engine noise and lower emissions.

It is not advisable to modify these maps unless you are confident you understand them.

Injection Quantity Limit

This 2D map limits the maximum amount of Injection Quantity allowed in mm3.

Sensor Scaling

MAF Sensor scaling

This 2D map only needs adjusting if the Air Intake Tube, that contains the MAF sensor, is replaced for a larger housing. There is no need to adjust this otherwise.

Torque

Desired Torque and Maximum Allowed Torque

Desired Torque table can be used to increased torque output on part throttle.

If you Increase the torque value in the Desired Torque table then you may not actually achieve that higher Desired Torque Value due to the MAXIMUM TORQUE limit maps.

There are several MAXIMUM TORQUE maps, the ECU does swap between them for different vehicle speeds and conditions, so be sure to alter all MAXIMUM TORQUE maps by the same amount.

NOTE : Just because you desire 420NM does not necessarily mean the Maximum Torque Yaxis Input will be 100% of the Desired 420NM , many other factors like vehicle speed, Coolant Temp , Air Temp , Atmospheric Pressure and any learning or Torque Reduction tables may reduce the Desired Torque value proportionally.

In our experience the ECU normally uses around 90 to 95% of the Desired Torque assuming the engine is up to temperature and Air temperature is not too high.

Torque Reduction maps

There are various Torque reduction maps for air temp, coolant temp and vehicle speed (or Per Gear). Reduction from high coolant temp can stop the engine overheating whilst pulling a heavy load up a long steep hill. Per Gear maps are useful to reduce engine torque output in a low gear or in 4WD LOW where Engine Torque Output is multiplied to enormous values at the wheels, which could easily break gearboxes or differentials.

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

If you do not fully understand this product then you WILL damage your engine, ECU or your vehicle.

Please ensure you fully read all EcuTek manuals BEFORE attempting to use ProECU with your laptop or your vehicle.

Use with extreme caution and understanding at all times, if in doubt then do not proceed.

EcuTek accepts no responsibility for any damage to the engine, ECU or any part of the vehicle that results directly or indirectly from using the product.

** If you are in any doubt that you do NOT have the experience required to use this product then you should NOT USE IT **

Retail customers

** If you have any doubt that you do NOT have the experience required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner use it for you **

(+44) 1895 811200 When dialing from within the UK, the country code is not required so dial 01895 811200 Open Hours Monday to Friday 9:00am - 5:00pm BST (UK Time) (4am-1230pm Eastern Standard TIme US) Visitors by appointment only EcuTek Tehnologies Ltd.Contact Us:

8 Union Buildings

Wallingford Road

Uxbridge, UB8 2FR

England

VAT No: GB 235 2616 23