VR30DDTT RaceROM Flex Fuel

Brandyn Mowat

Lucan Hetherington

Intro:

EcuTek RaceROM is a package of special software features that can be installed into the ECU of the supported vehicles. You simply open your ECU ROM file using EcuTek software, apply the RaceROM Feature File (Patch) to it, adjust the RaceROM maps as necessary, and then program the ROM file into the vehicle. Please read the ProECU Tuning RaceROM Feature File Guide for info on how RaceROM works, how to install and uninstall RaceROM feature files, and further hints and tips. Please also see our website for various videos and webinars for further information.

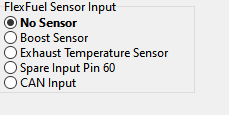

Flex Fuel can Now be done with CAN Inputs as well. Please see the VR30DDTT Custom Sensor Input Setup guide to set these up

Flex Fuel

FlexFuel support was added as an integral part of the Phase 3 RaceROM upgrade. It uses a similar strategy to BRZ/GT86 and Nissan GT-R. This strategy utilizes ignition and AFR target modifier maps for 100% E85 as well as 2d maps to determine how much of that modification is applied. The difference in base fuel requirement is taken care by the FlexFuel Quantity Multiplier map and a 2d blend map. Typically, ~40% extra fuel will be required for 100% E85 to maintain the same Lambda (therefore the same reported petrol AFR), and the transition will be quite linear. The change in ignition advance will probably more readily be applied with most, if not all of the additional advance added by 50% E85. Currently the patch is supplied with typical values used in the FlexFuel Quantity Multiplier map so that any car with a FlexFuel sensor added should start and run reasonably well when E85 fuel is added. Remaining correction maps for ignition and AFR target are blank, and the FlexFuel Target Boost map has default values identical to those found in the Target Boost map.

Typical Tuning Steps

If the vehicle has already been tuned on E10, you can likely math out what your values should be on E0 and E100 knowing the increased fueling demands and knock resistance of ethanol. Being relatively conservative with the fueling and ignition timing changes at first is typically the safe course. After you've confirmed the car runs safely on E10 with the changes you made, Increasing the ethanol content up to ~50% and then verifying it's operation again prior to adjusting fueling/ignition timing.

Table of Contents

How to Enable Flex Fuel

In order to enable the EcuTek RaceROM Flex Fuel system all you'll need to do is set a sensor input in the FF Sensor Source map.

Boost Limit Fuel Cut Blend

Percentage modifier to the boost limit where fuel cut will occur based on the ethanol content.

Boost Limit Fuel Cut Ethanol

Boost limit in Bar. This parameter is modified by the value in the Boost Limit Fuel Cut Blend set by map slot. Set this value in order to run a different boost limit when running flex fuel.

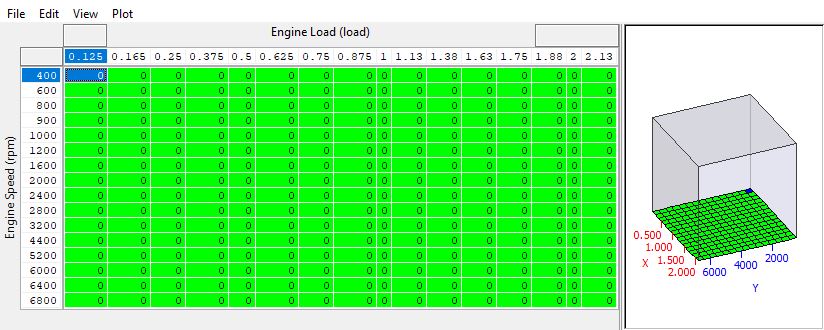

FF Boost Target Blend

Percentage modifier to the boost target based on the ethanol content. Typically set so that a higher percentage of the boost target is used as the ethanol content increases.

FF Cranking Multiplier

The fuel quantity at cranking will be affected by the Flex Fuel Cranking Quantity Multiplier map. Due to the characteristics of the fuel, it may be required to change the fueling further at low temperatures when cranking. This map is 0-2 scalar and will multiply the base fueling only during cranking based on coolant temperature, it is not unusual to need additional E85 when cold due to some unburnt fuel going through the engine.

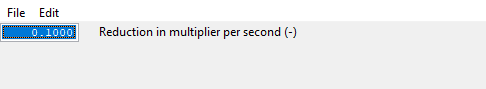

FF Cranking Multiplier Decay Rate

This decay rate applies a gradual reduction to the FF Cranking Multiplier value amount per second. As such it reduces the FF Cranking Multiplier by a set amount every second starting from the beginning of the start cycle.

FF Cranking RPM Threshold

Once your engine has exceeded this RPM level, the additional fuel added during cranking by the FF Cranking Multiplier will start decaying as designated by the FF Cranking Multiplier Decay Rate.

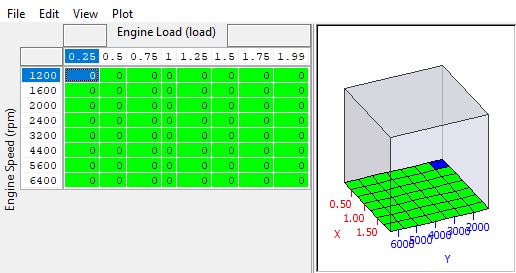

FF Ethanol Content Hold Engine Load

Particularly with direct-injected vehicles it's not unusual to a slight fluctuation in your sensor readings due to aeration of the fuel. To minimize the impact of this on your vehicle's operation, the ethanol content employed by the flex fuel strategy can be temporarily locked when your vehicle is operating under high load conditions. This map sets a load limit. When this limit as well as the engine RPM level in the FF Ethanol Content Hold RPM map is exceeded, the flex fuel ethanol content will be fixed until one of the two thresholds are no longer met.

FF Ethanol Content Hold RPM

In conjunction with FF Ethanol Content Hold Load this can be used to lock the ethanol content when fuel flow is maximised.

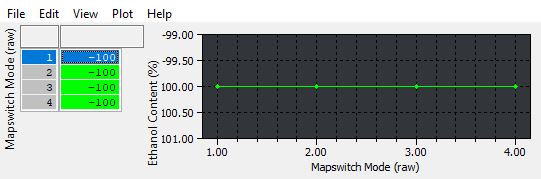

FF Ethanol Content Override Percent

For instances where an ethanol content sensor isn't installed or where it isn't practical, Pre-mixed ratios of alcohol can now be catered for in the RaceRom Flex Fuel strategy by entering the ethanol content in this map. You do so by setting a specific target for each map slot. -100 disables this feature for each map slot.

FF Fuel Pump Angle Addition Blend

Sets a percentage blend for the amount of fuel pump angle being added in based on ethanol content.

FF Fuel Pump Angle Addition Max

Sets the maximum amount of fuel pump angle that can be added to the base fuel pump angle.

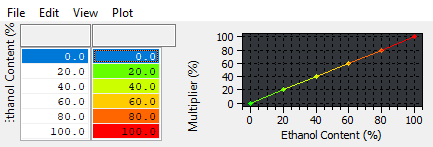

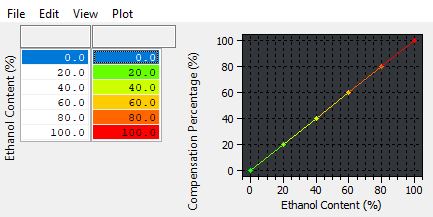

FF Ignition Timing Addition Blend

The values are a multiplier of the FF Ignition Timing Max Addition values and dictate how much of that advance is added for a given Ethanol content. The resulting ignition advance is calculated as

Final Ignition TIme = Ignition TIming + (FF Ignition Addition Blend x FF Ignition Max Addition)

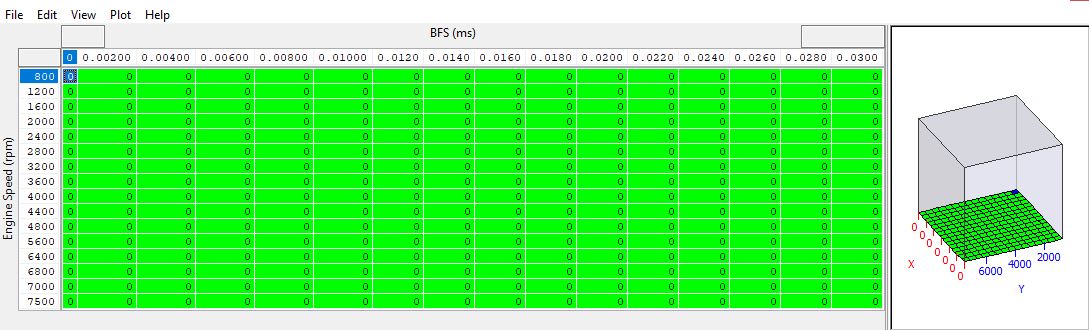

FF Ignition Timing Addition Max

Additional timing to be multiplied by the FF Ignition Timing Addition Blend before being added to the Ignition Timing. This represents the absolute maximum ignition advance that can be added. The timing is added in proportionally to the value found in the FlexFuel Ignition Timing Addition Blend map.

FF Knock Threshold Addition Blend

A percentage adjustment value for the FF Knock Threshold Addition Max before adding it to final values.

FF Knock Threshold Addition Max

Adjustment table for the knock threshold when running flex fuel. Modified based on the FF Knock Threshold Addition Blend percentage.

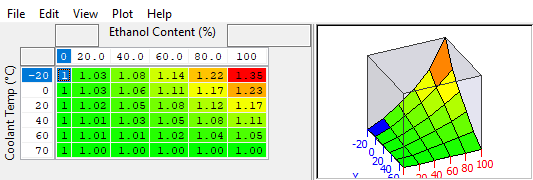

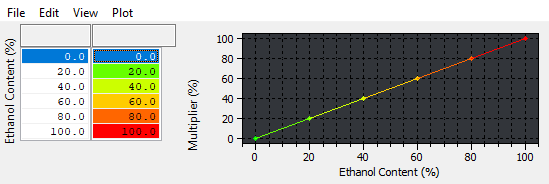

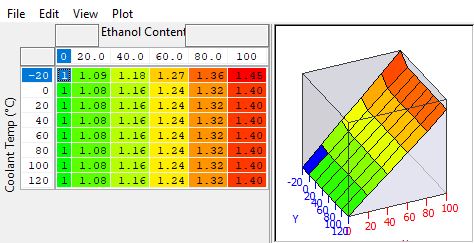

FF Quantity Multiplier

This dictates the additional fuel based on ethanol content (0-100%) and coolant temperature. It would not be unusual to need to add additional E85 when cold due to some unburnt fuel going through the engine. Pure Ethanol typically requires 40% more fuel to maintain the same lambda (or apparent AFR) as gasoline. There are no significant changes to injector flowrates when using E85.

If you want to run a richer or leaner AFR when using E85 do not try and compensate with this map as the ECU will use fuel corrections to hit the same target AFR target, instead use FF Target AFR Addition Max.

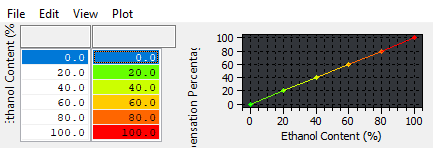

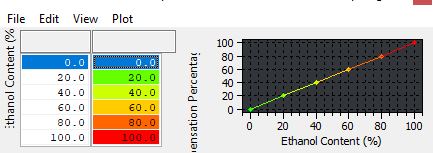

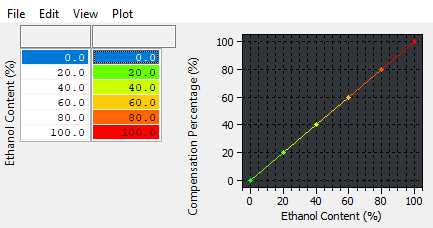

FF Target AFR Addition Blend

This map dictates how much of the AFR change is used for a given Ethanol content. The resulting AFR Target is defined as.

Final AFR Target = Target+ (FF Target AFR Blend x FF Target AFR Addition Max)

FF Target AFR Addition Max

This map utilizes units of AFR as the units. Use of a positive number will add to the preceding target AFR resulting in a leaner final AFR. Left blank by default, the pictured table uses +.5 at high load in order to lean out the AFR from (for example) 11:1 at very high load on pump fuel to a cleaner and crisper 11.5:1. However if the base map is made already using a good fuel or even a race fuel that would typically run closer to 12.2:1 then it would be entirely possible to want to lower the target AFR when using high levels of E85.

The final AFR target is the result of this map weighted by the result of FF Target AFR Addition Blend

Sensor Calibration

FF Sensor Default

In the event of a sensor or wiring failure, the ethanol content value specified in this table will be used.

FF Sensor Max

The maximum voltage output of the ethanol content sensor. Set this to the value specified by your ethanol kit's manufacturer.

The ecu itself has a default voltage biasing of 4.75v on the spare ECU input pin (Pin 60). As such using that specific voltage can cause erratic behavior. It's recommended to go either above or below that value to ensure proper operation.

FF Sensor Min

The Minimum voltage output of the ethanol content sensor. Set this to the value specified by your ethanol kit's manufacturer.

FF Sensor Scaling

The scaling specified by your ethanol kit's manufacturer for voltage for a given ethanol content percentage.

FF Sensor Smoothing

A smoothing value to be applied to the output of the ethanol sensor to reduce the impact of the minor fluctuation in content seen by most ethanol sensors.

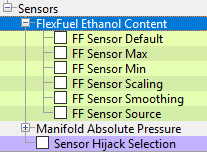

FF Sensor Source

Selecting a sensor input will also enable the EcuTek Flex Fuel system.

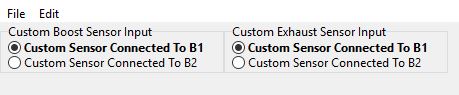

Enables the selection of which position you'd like to hijack/input ethanol content into. You can choose between an EGT, or boost pressure sensor on either bank which is selectable in the Sensor Hijack Selection.

Sensor Hijack Selection

Chooses which bank's sensor (as selected in FF Sensor Source) is used as the ethanol content sensor input.

Flex Fuel Sensor Setup/Wiring to ECU

Unlike other platforms, we were able to find an unused ECU channel into which we were able to input a signal from an ethanol content sensor. To do so you'll need to pin it into the ECU. While the placement of the wiring and ethanol sensor may vary based on the manufacturer of the kit, it will need to be input through the same point in order to work properly with our software.

You'll want to add the 0-5v signal outputted from your sensor or gauge to pin 60 of connector F143 on the ECU.

Flex Fuel CAN Sensor Setup

As with other platforms, we were able to integrate CAN communications to input a signal from an ethanol content sensor. To do so you'll need to find a place to it into the CAN bus system directly connected to the ECU. you will need to follow the CAN equipped ethanol content sensor instruction to find the appropriate sensor positions and wiring.

Configuration of the can messaging system is shown in the RaceROM CAN Inputs article VR30DDTT Custom Sensor Input Setup.

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

If you do not fully understand this product then you WILL damage your engine, ECU or your vehicle.

Please ensure you fully read all EcuTek manuals BEFORE attempting to use ProECU with your laptop or your vehicle.

Use with extreme caution and understanding at all times, if in doubt then do not proceed.

EcuTek accepts no responsibility for any damage to the engine, ECU or any part of the vehicle that results directly or indirectly from using the product.

** If you are in any doubt that you do NOT have the experienced required to use this product then you should NOT USE IT **

Retail customers

** If you have any doubt that you do NOT have the experienced required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner to use it for you **

Update Revision Log

Added RaceROM Flex Fuel see tuning guide here - VR30DDTT RaceROM Flex Fuel

Allows sensor input through sensor hijack or the addition of an ECU pin

Added the ability to add a Fuel Pressure Sensor

Allows sensor input through sensor hijack or the addition of an ECU pin

Added sensor hijack torque limit to go into a failsafe mode if a sensor goes out of range.

RaceROM Map Switching via cruise control buttons (before only possible via EcuConnect App)

Valet Mode Enable/Disable via cruise control buttons (before only possible via EcuConnect App)

Separately Scalable Manifold Pressure Sensor Scaling (Previously scaling was shared with the pre-throttle boost sensors)

Quality of life improvements

Fans switched off during programming

No more delay for reading EEPROM data i.e. saved map switch mode.

Added RaceROM Launch Control BETA

One click toggle to disable all RaceROM features (Except logging) allows calibration of stock tables.

(+44) 1895 811200 When dialing from within the UK, the country code is not required so dial 01895 811200 Open Hours Monday to Friday 9:00am - 5:00pm BST (UK Time) (4am-1230pm Eastern Standard TIme US) Visitors by appointment only EcuTek Tehnologies Ltd.Contact Us:

8 Union Buildings

Wallingford Road

Uxbridge, UB8 2FR

England

VAT No: GB 235 2616 23