GT-R RaceROM Tuning Guide

Boost Gauge Rescaling

The boost gauge can be rescaled, and/or made to wraparound in order to display boost pressures in excess of the limitations of the standard gauge.

The Boost Gauge Rescale feature allows the tuner to rescale the boost gauge in order to accurately display the level of boost when it exceeds the normal factory scaling. Please note that it is not possible to change the numbers on the gauge at this time and this feature will NOT change Target or Actual boost values, only the boost gauge display will be rescaled.

Examples of boost gauge rescaling

Example 1

Boost Gauge Multiplier: 1

Boost Gauge Offset: -1.0

| Manifold Relative Pressure | Gauge Reading |

|---|---|

| 0.00 | -1.00 |

| 0.50 | -0.50 |

| 1.00 | 0.00 |

| 1.50 | 0.50 |

| 2.00 | 1.00 |

| 2.50 | 1.50 |

Example 2

Boost Gauge Wrap Threshold: 1.5

Boost Gauge Wrap Subtraction: 2.5

| Manifold Relative Pressure | Gauge Reading |

|---|---|

| -1.00 | -1.00 |

| -0.50 | -0.50 |

| 0.00 | 0.00 |

| 0.50 | 0.50 |

| 1.00 | 1.00 |

| 1.50 | 1.50 |

| 2.00 | -0.50 |

| 2.50 | 0.00 |

| 3.00 | 0.50 |

RaceROM Boost Controller (not to be confused with RaceROM Boost Control

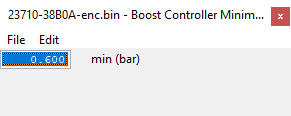

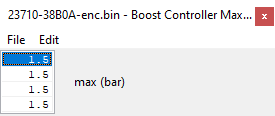

The RaceROM Boost Controller feature allows the driver to adjust the maximum desired boost using the cruise control buttons (when the cruise control is off). The boost level selected is displayed on the dashboard monitor.

- Ensure the cruise control is switched off.

- Press "RES/ACCEL" or "COAST/SET" to display the current desired boost.

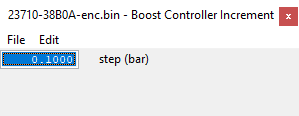

- To increase desired boost by 0.1 bar, press "RES/ACCEL"

- To decrease desired boost by 0.1 bar, press "COAST/SET"

- To increase desired boost to maximum, hold "RES/ACCEL" for 2 seconds.

- To increase desired boost to minimum, hold "COAST/SET" for 2 seconds.

- After 2 seconds, the monitor display will revert to normal.

Configuration

The RBC feature operates as an upper limit on the desired boost. The feature will not increase the boost above the level set in the ECU desired boost map. For this reason, you must ensure that the ECU Desired Boost is set to the same or higher value than the RBC Max Boost. You should also set the Desired Boost Limit maps accordingly.

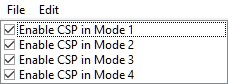

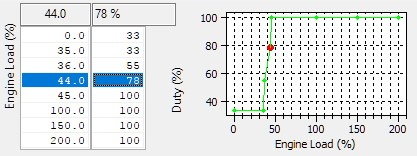

Per Gear Boost Control

The Per Gear Boost Control feature (Mode 1 to Mode 4) allows you to adjust the target boost based on Gear and RPM. This can be used to provide a higher boost level in lower gears for rapid acceleration while maintaining the standard boost level for cruising in the higher gears. The ECU will apply a multiplier to the Desired Boost based on RPM and Gear.

Integration with Map Switching Feature

Separate per Gear Boost maps are provided for each of the map switching modes.

Related Maps

Per Gear Boost Mode1,2,3,4

These maps define a percentage multiplier based on RPM and current Gear. The multiplier is applied to the ECU Desired Boost Table.

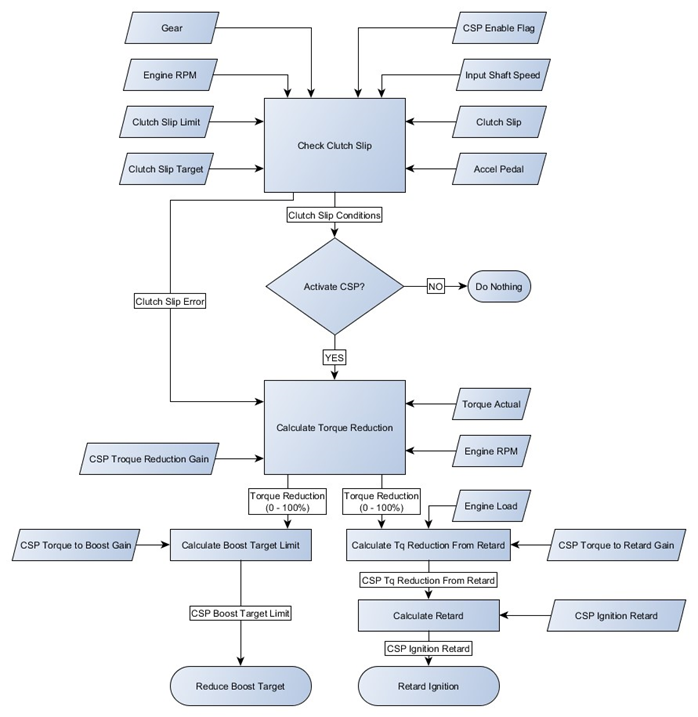

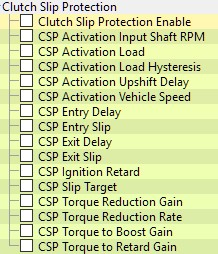

Clutch Slip Protection

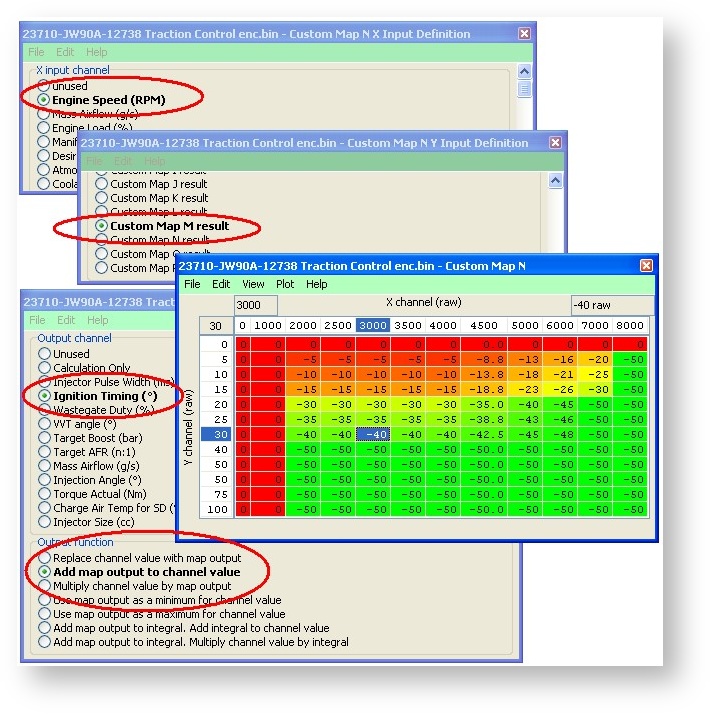

To meet the increasing demands of higher and higher power levels being achieved on a reprogrammed factory ECU, we have added a strategy to adjust the power output to control and prevent clutch slip. This can be used to both impose a torque limit and/or retard the ignition to temporarily reduce power to halt clutch slip to acceptable levels.

This strategy will cater for instances where the TCM does not send a torque reduction request after a launch.

Operation

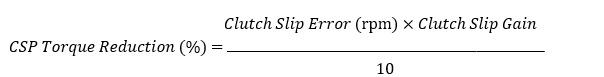

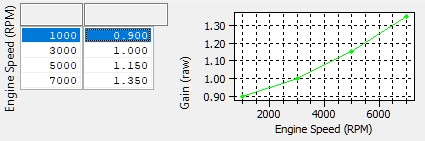

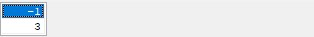

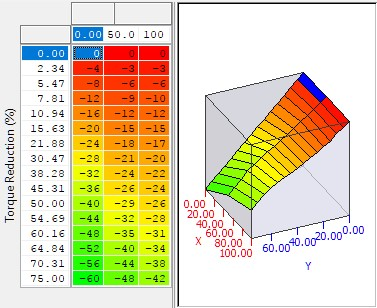

Once slip exceeds CSP Entry Slip for a time exceeding CSP Entry Delay then CSP becomes active and it reduces the power using ignition retard and reduced boost target. The strategy will try to bring the clutch slip down to CSP Slip Target and remains active until Clutch Slip drops below CSP Exit Slip for a time exceeding CSP Exit Delay.

The CSP Torque Reduction Gain map is used to change the overall torque reduction response to clutch slip, the CSP Torque to Boost Gain and CSP Torque to Retard Gain determine how that torque reduction is achieved, this is detailed below.

Map List

Live Data Parameters

- Clutch Slip (RPM) – Define as Engine Speed – Input Shaft speed in RPM. This can be negative as the engine speed increases to match shaft speed, typically on a downshift.

- Clutch Slip Error (RPM) – Difference between the current clutch slip and the target clutch slip, positive values mean more slip than desired.

- Clutch Slip Timer (Seconds) – Elapsed time that clutch slip has been over the limit while all other conditions for entering Clutch Slip Protection have been met. The timer stops once the timer reaches CSP Entry Delay.

- Clutch Slip Exit Timer (Seconds) – Elapsed time that clutch slip has been below CSP Exit Slip, the timer stops once timer reaches CSP Exit Delay.

- Clutch Upshift Timer(Seconds) – Elapsed time since an upshift was detected due to an increase of current gear.

- CSP Flags – Combination of flags used for diagnostic purposes by EcuTek

- CSP Ignition Retard (degrees) – Amount ignition timing has been retarded due to Clutch Slip Protection.

- CSP Boost Limit (Bar) – Boost Target Limit imposed due to Clutch Slip Protection.

- CSP Torque Reduction (%) - Current torque will be reduced by this percentage if CSP becomes active. Used as input on Y axis to Clutch Slip Retard

CSP Flags

1 = Outside upshift exclusion time

2 = Minimum slip condition met

4 = Minimum input shaft speed condition met

8 = Minimum load condition met

16 = Minimum Slip error condition met

32 = Minimum vehicle speed condition met

128 = Clutch slip control is active

Note: These values are displayed as a sum e.g. 3 = 1 +2 = Outside upshift exclusion time & Minimum slip condition met

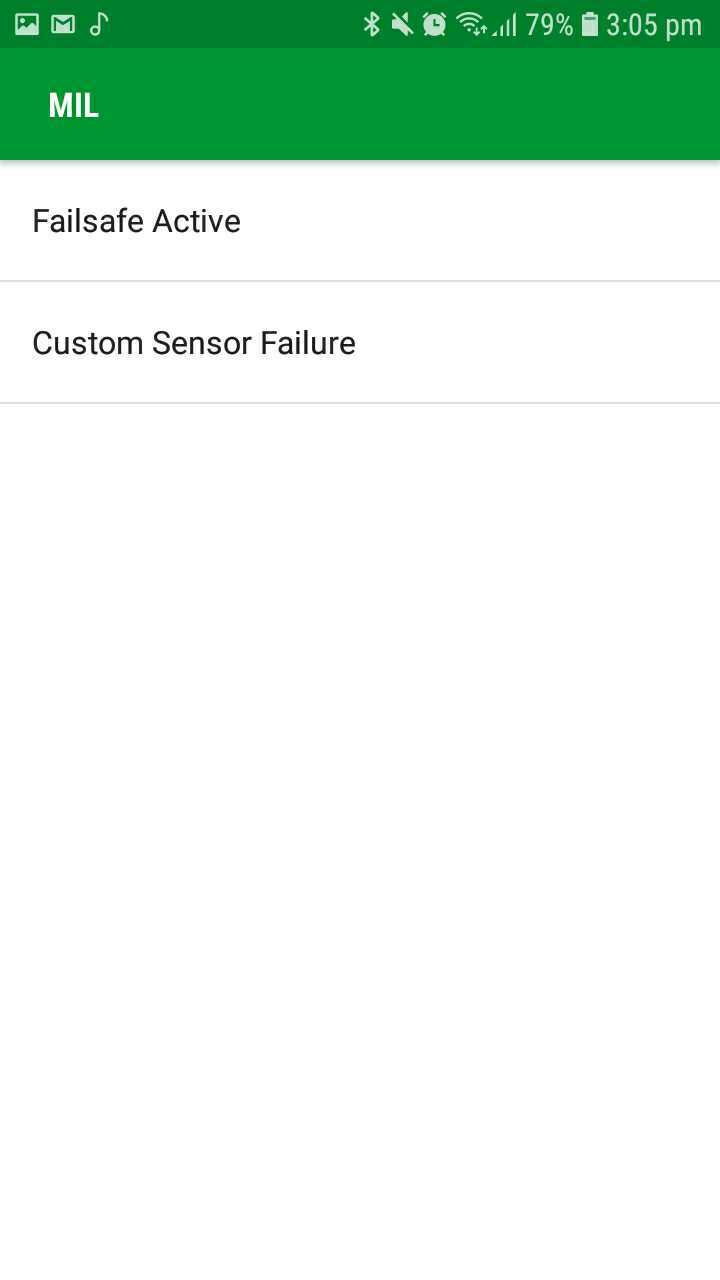

Check Engine Light (MIL) flashes and ECU Connect parameters

To improve diagnostics the MIL source parameter was added so that you know what the check engine light flashes are caused by. The following is a list of the numbers and outputs from the ProECU live data parameters.

| Value | Warning |

|---|---|

| 01 | Failsafe |

| 02 | Knock Warning |

| 04 | Clutch Slip |

| 08 | Custom Sensors (Voltage out of Range) Failure |

| 31 | All |

| 48 | Beta (reserved) |

| 64 | Live Tuning |

| 128 | Custom Maps Failsafe |

the ECU Connect page is Called MIL and displays the warning values as the text values above

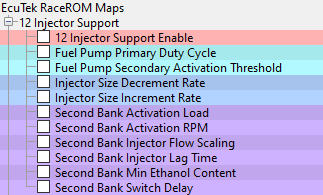

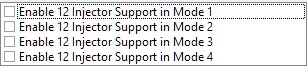

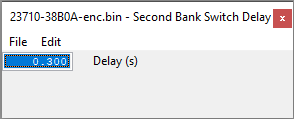

12 Injector Support

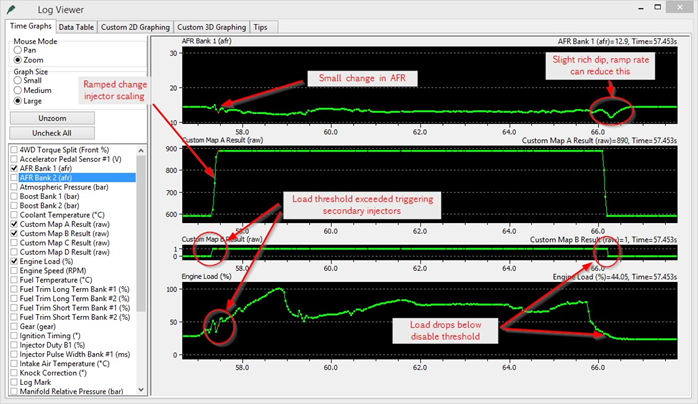

A simple but effective 12 injector strategy has been implemented that allows 12 injectors to be run on the GTR using additional hardware. Due to the limited spare outputs and the difficulty of fundamentally changing the low level scheduling of outputs, 12 injector support is achieved by switching a secondary bank of injectors on at low to moderate load while scaling the injector constant during a “ramp in” period. The secondary air solenoid is the only output currently available to use with this feature. Details on how to implement this are available on request.

Operation

The below screenshots shows the various stages of activating and deactivating the secondary Injectors

Map List

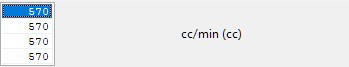

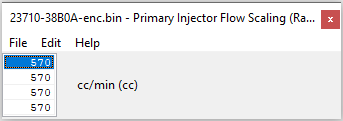

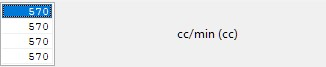

Large Injector Support

The standard ECU supports a maximum injector size of 800cc. RaceROM removes this limitation so you can fit larger injectors. RaceROM also offer different Injector size configurations for each of the 4 map switch modes enabling dual fuels to be used (example E85 the value could be decreased by around 25% therefore increasing each Injector open time period by 25%)

When using RaceROM Feature File Phase 3 or newer the factory Injector Flow Scaling map is not used anymore and should be ignored

Injector Flow Scaling (RACEROM)

This map is used instead of the normal Injector Flow Scaling map. Separate values can be specified for each map switch mode.

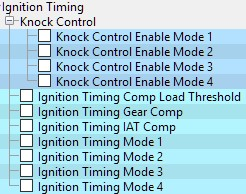

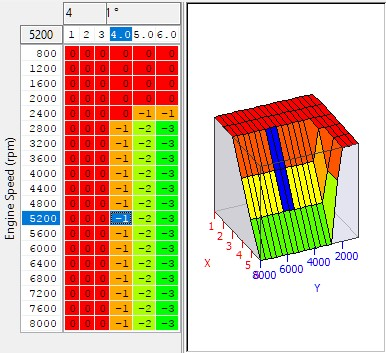

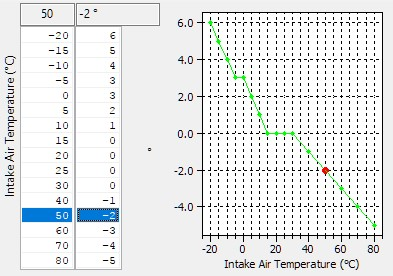

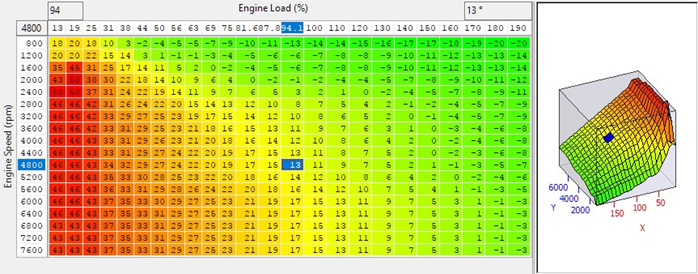

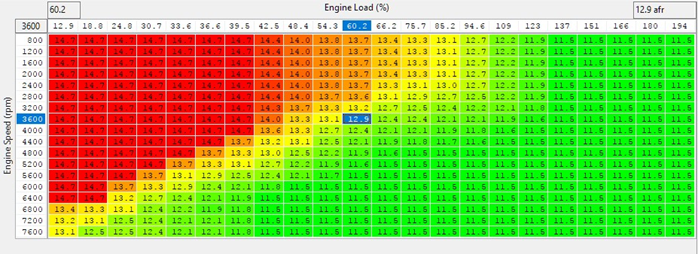

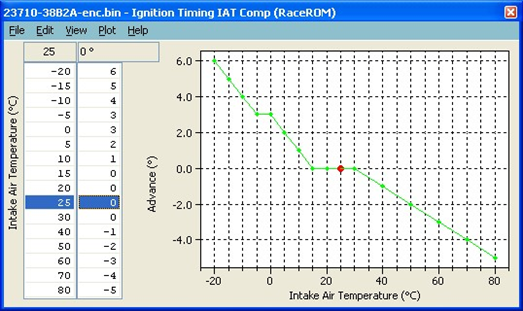

Ignition Timing (RaceROM Simplified)

timing strategy is very good when applied to a stock car but difficult and restrictive to tune for high power applications. RaceROM adds easy to use larger maps with high precision load input axis for improved control and range. Supporting maps are also added for further safety.

Some OEM maps are included here for convenience, but not all are covered in this guide yet.

Map List

Live Data Parameters

- Ignition Timing (°) – Current actual ignition timing in degrees BTDC, negative means ATDC

- Ignition Timing Calculated (°) – Ignition timing as calculated by the OEM strategy

- Knock Correction (°) – Offset due to knock, negative is retard, positive is dynamic advance on GEN 2

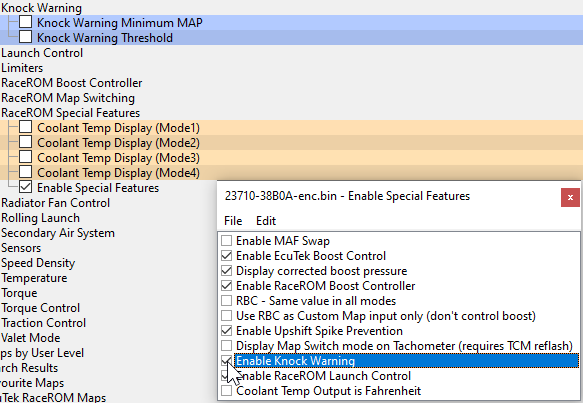

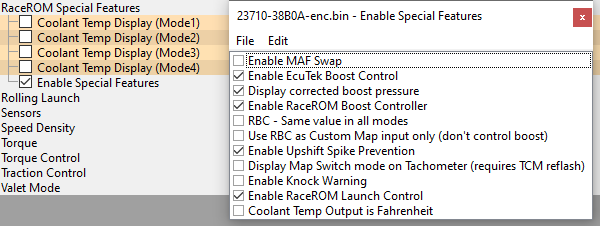

Knock Warning

A simple driver warning for excessive knock control activity, flashing the CEL when triggered by knock retard. The ECU retards ignition timing when knock is detected. When the amount of retard exceeds the threshold, and increases further, the Check Engine Light will flash rapidly three times.

Map List

Launch Control

The Nissan GTR has a built in factory Launch Control Mode, when conditions are correct this will deliver an extremely effective launch condition. When entering the special mode the throttle butterfly will react quickly providing a burst of Engine Torque which will load the transmission and drivetrain for a blistering launch condition.

This launch condition is often mistaken and confused for the typical ‘stall test’ launch that can be induced by on most Auto gearboxes models at the traffic lights (left foot on the Brake, Accel pedal to the floor and wait for the lights to change). This low torque/low RPM slipping convertor/clutch launch is not the same or nearly as aggressive as the special Launch Control Mode, though this type of launch is still very effective on the GTR when used.

From 2008 to 2013 each new version of the GTR had a revised launch behaviour, and these have been broadly categorised as LC1 to LC5 by EcuTek and its competitors. The LCx nomenclature is not official Nissan terminology, although some Nissan dealers will understand the term. There appear to be five different LC strategies, however there are not 5 distinct versions of TCM rom with different LC strategies, some ROMs use the same strategy with different map an data values resulting in different behaviour for the drive, some LC versions the result of different ECM maps.

For more information check out

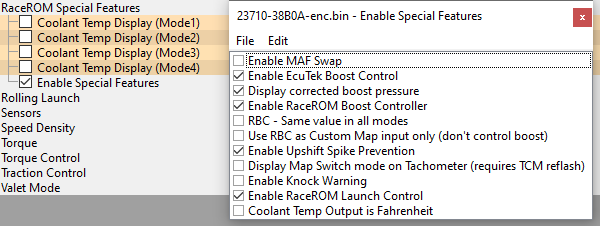

MAF Bank Switching

The MAF Bank Switching feature allows you to correct the airflow measurement after fitting an aftermarket intercooler that swaps the airflow between the left and right banks of the engine. Some aftermarket intercoolers swap the airflow between the left and right banks of the engine having the air flow across the intercooler core, as opposed to the factory style where it loops back around to the same side throttle. This feature compensates for the mechanical alteration by swapping the MAF sensor readings between left and right banks.

Only check this box if the new Intercooler swaps the Intake flow between banks otherwise the ECU will be looking at the wrong throttle butterfly and wrong MAF sensor (for Mass Airflow reading) when controlling Idle and during Idle balance.

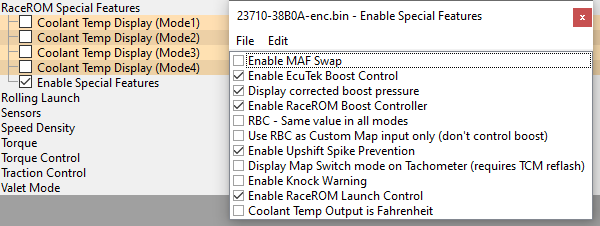

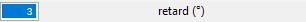

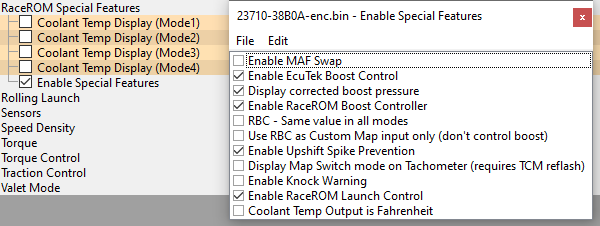

Enable Special Features

This Map contains the checkbox for the Enable MAF Swap feature.

Stock-Style AMS Intercooler

Greddy Cross-flow style intercooler

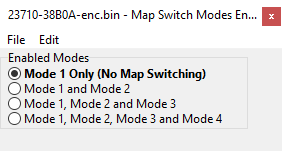

Map Switching

The Map Switching feature allows you to up to define four different calibrations in the ECU ROM. The driver can switch between the calibrations at the press of a button. It is envisaged that this feature will be used to provide a comfortable calibration for everyday road use and a hard-core maximum performance calibration for use at the track. Alternatively you could use this feature to provide four calibrations optimised for different grades of fuel.

The Map Switching feature is enabled by the Map Switch Modes option list in the RaceROM Special Features section. When this feature is operational, the ECU can be programmed with up to four different calibrations and the driver can switch between them.

You can optionally display a number for each mode on the coolant temp display, perhaps to remind the driver the octane level of fuel that this mode has been optimized for.

Switching between modes

The driver can select the map switch mode by holding down the cruise control "Cancel" button for 1 second when the cruise control is switched off.

The tachometer will move to 1000,2000,3000 or 4000, to indicate mode 1,2,3 or 4.

The mode number may optionally be displayed on the coolant temp gauge.

The driver can adjust the mode by using the cruise control Set/Cst and Res/Acc buttons. After selecting the desired mode, press “Cancel” again to save it.

Integration with other RaceROM Features

- Per Gear Boost Control Feature - The Per Gear Boost Control feature has separate maps for each of the four modes.

- RaceROM Boost Controller (RBC) Feature - The driver can set different boost levels for each of the four modes. The tuner can set a different maximum limit for each mode.

- Per Gear Rev Limits Feature - The Per Gear Rev Limits feature has separate maps for each of the four modes. The TCM will need to be in R-Mode to exceed 7000rpm gear change point.

- Large Fuel Injectors Feature - The Large Fuel Injectors feature has separate maps for each of the four modes. This can be used for multi-fuel set-ups like 92 Octane, 97 Octane, RaceGas and E85 in each of the four modes.

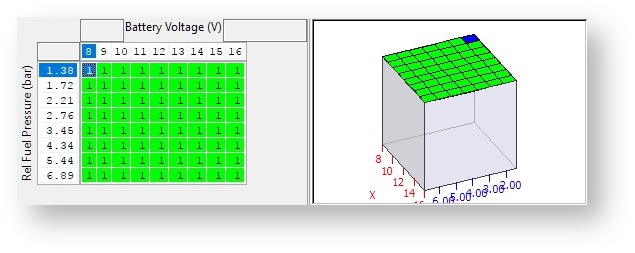

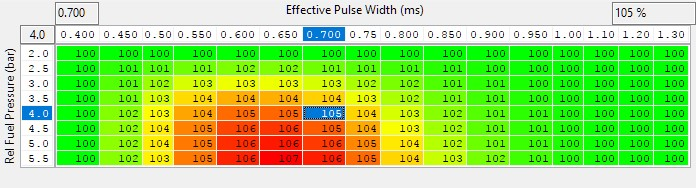

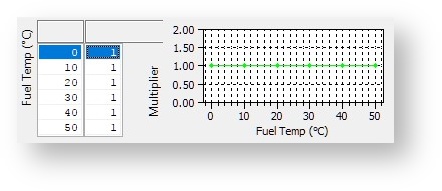

Fuel Temp Compensation

When tuning a car with a fuel temperature sensor, it is now possible to compensate for changes in the fuel temperature. Typically fuel pulsewidth is increased with increasing fuel temperature to compensate for the drop in fuel density, numbers greater than 1.0 will increase injector effective pulsewidth.

The table below outlines the approximate multiplier required to correct for a difference in fuel temperature.

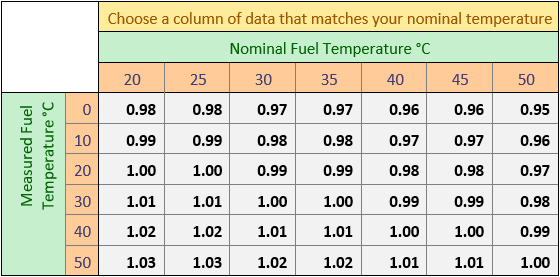

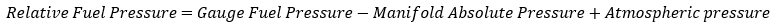

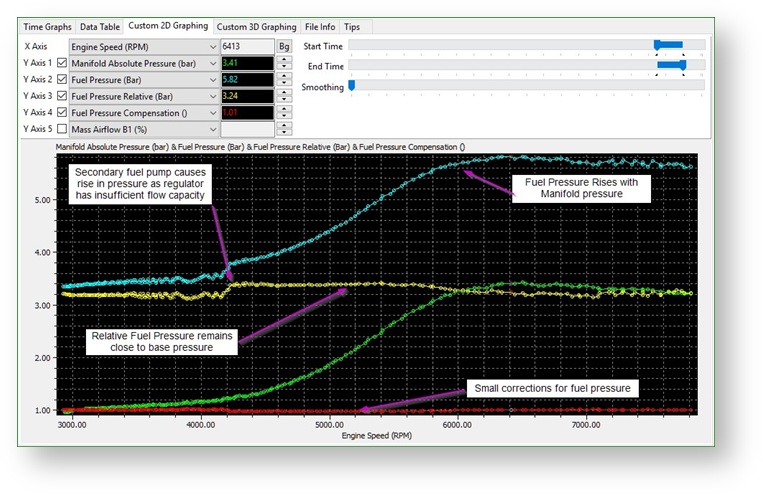

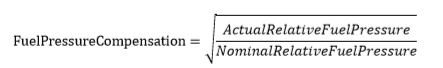

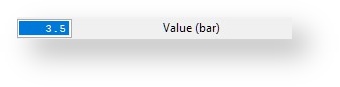

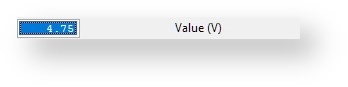

Changes in fuel pressure can be compensated for using this new map, in conjunction with an additional sensor configured using the new sensor options. For the purposes of this correction Relative Fuel Pressure is used and represents the pressure difference between the inlet (fuel rail) and nozzle (inlet port) pressures, defined as:

The below example is shown using a nominal fuel pressure of 3.5bar (50.75 psi)

This is demonstrated in the graph below showing that while the pressure in the fuel rises with manifold pressure the relative pressure remains consistent, only varying due to the limits of the regulator when the second pump activates.

At close to sea level with an atmospheric pressure of 1.0 bar this would result in a relative fuel pressure of 3.6 bar if the Gauge Fuel Pressure was 4.9 bar at 2.3 bar MAP (1.3 bar relative boost).

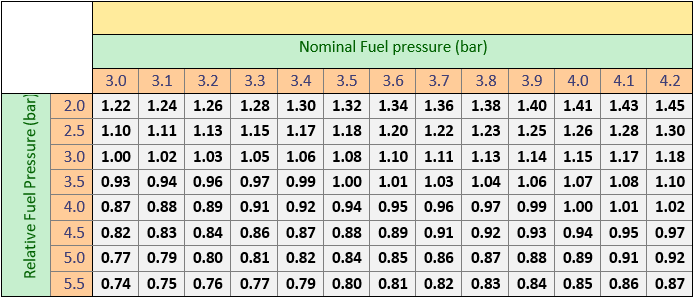

Within the normal range of fuel pressure the injector pulsewidth should be multiplied according the following approximation.

Below are examples of how to populate this table for common base fuel pressures in bar

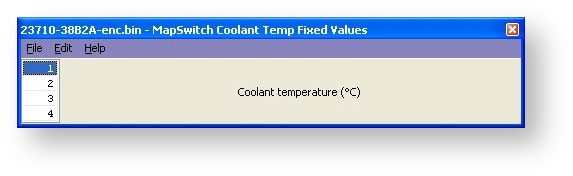

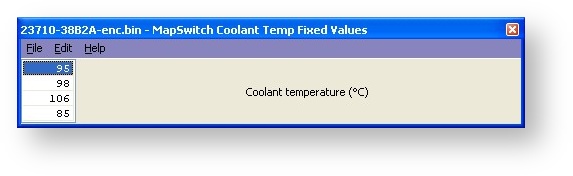

Coolant Temp display during Map Switch

The four ignition maps can be calibrated for different fuel, in addition we can change the values shown on the Coolant Temp Gauge during Map Switch Mode to indicate the fuel currently in the fuel tank.

| Map Switch Mode | Coolant Temp Gauge Display | Sugesting Fuel Type |

|---|---|---|

| Ignition Timing Mode1 | 95 | 95 RON |

| Ignition Timing Mode2 | 98 | 98 RON |

| Ignition Timing Mode3 | 106 | 106 Octane Race Fuel |

| Ignition TIming Mode4 | 85 | Ethanol Based Fuel (E85) |

Default values shown on the Coolant Temp display when Map Switching

Example values that could be shown on the Coolant Temp display when Map Switching

When MODE 1 is selected the Coolant Temp gauge will show 95 (203F)

When MODE 3 is selected the Coolant Temp gauge will show 106 (228F)

NOTE: The units are in Deg C (Celsius) but on US models the values will be displayed in

Fahrenheit . So you will need to reduce the Deg C values so the correct Fahrenheit value is shown on the display. Google offers a simple online conversion.

In addition by using the Rev Counter tacho indication for Map Switch Mode then we still have a visual indication of Modes 1 to 4 (requires TCM programming with the latest RRFF version for Tacho Indication).

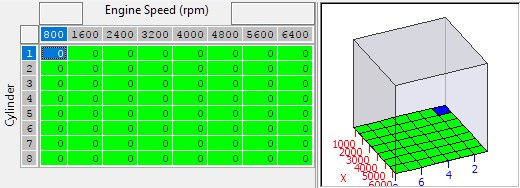

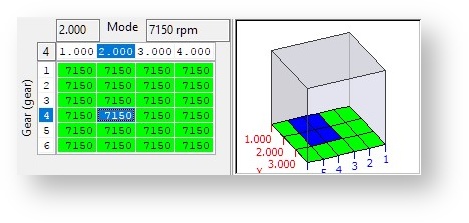

Per Gear Rev Limits

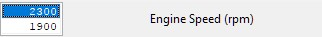

Easy to use rev limiter that employs a 100% fuel cut with hysteresis. Calibratable based on Map Switch Mode and Gear.

The Per Gear Rev Limits features allow you to define different rev limits for each gear. By setting a higher rev limit in lower gears you may be able to reduce the number of gearshifts required in attaining a given speed. E.g. 0-60mph or 0-100km/h tests.

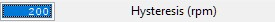

To simplify the setting of the fuel cut based rev limits, they now all appear in one 3d map and use a single 1d value to introduce hysteresis. The fuel cut will be active over the RPM value in this map, and fuel will only be restored when the RPM has dropped below this level by Rev Limit Hysteresis.

Be aware that GEN2 cars typically have a 7300rpm fuel based rev limit so you may wish to raise the defaults in this map to match the stock limit.

Rev Limit Hysteresis

Hysteresis value used when Rev Limit Per Gear has been triggered.

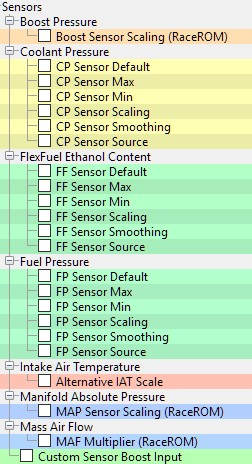

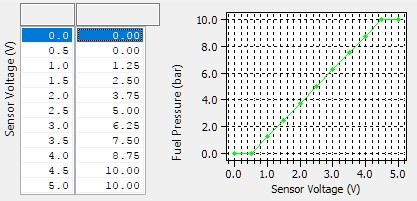

Sensor Scaling & Custom Sensors

Custom sensor inputs have been added for fuel pressure and coolant pressure, and extra functionality has been added to the existing FlexFuel sensor input, which now falls under the Sensors category with all the OEM and RaceROM sensors.

- Coolant Pressure – Coolant pressure (gauge) in bar

- FlexFuel Ethanol Sensor Output – Ethanol content as reported by the sensor output, including filtering

- Fuel Pressure – Total Fuel Pressure in bar (gauge) at the point of measurement

- Fuel Pressure (relative) – Filtered pressure differential across the fuel injector used for compensations and safety trips, also available as an input for custom maps. Correct values rely on the use of a fuel pressure sensor that returns gauge pressure (almost all do).

Map List

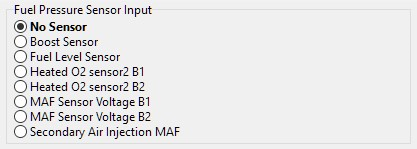

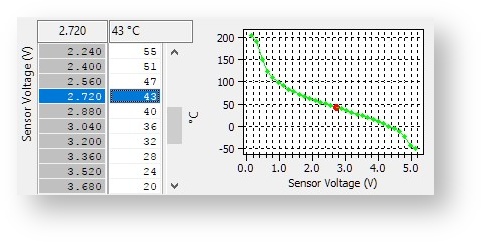

Custom Sensor Inputs

Due to the identical nature of each of these sensors, the common maps are only described for the fuel pressure sensor, but the same functionality applies to all the custom sensors.

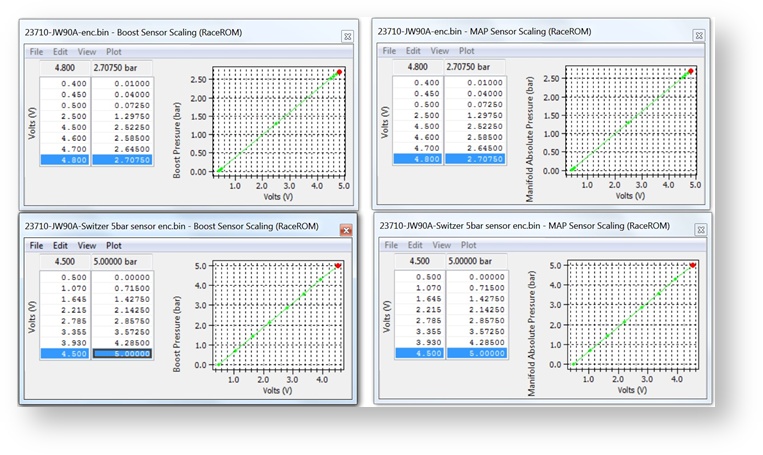

Custom Sensor Boost Input

If any of the custom sensor inputs are configured to use “Boost Sensor” as their source, the appropriate sensor must be selected here. If any sensor is configured to use “Boost Sensor” the voltage from the non-selected sensor is copied to redundant sensor input.

For example, if “Boost Sensor B1” is selected the follow should happen:

- The custom sensor will use the sensor input from B1 boost sensor.

- The B2 boost sensor input will be copied to the B1 Boost sensor.

- Both B1 and B2 boost values will get their value from the B2 sensor which is still connected.

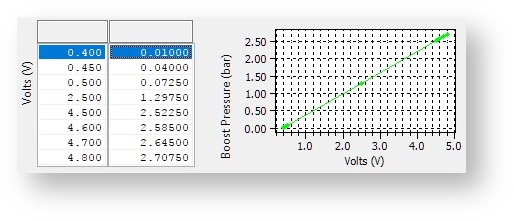

By using the RaceROM Hi Boost map feature we can increase the boost to 3 bar+.

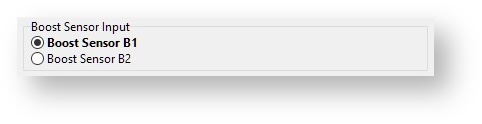

There are 3 MAP sensors fitted to the GTR and they are all 2.83 bar absolute sensors.

One MAP sensor is located in the plenum (Inlet manifold) and can show manifold vacuum, this MAP sensor is used for RaceROM Speed Density and the also the Boost Pressure display on the driver information display.

The other two MAP sensors are fitted pre throttle (one in each bank) and they are used for boost control and boost limit.

Any vehicle running more than 1.7bar boost will need 3 x new MAP sensors fitting pre and post throttle to be able to control boost pressures over 2.70bar absolute using the factory boost control system.

But if Custom Maps is used for boost control (where the plenum based MAP sensor can be used for the pressure reading) then the two pre throttle MAP sensors do not need to be replaced and the boost control can be based on the plenum based MAP sensor.

But please note that the boost limit is based on the pre throttle MAP sensors and if they are still stock items (2.83bar) then the boost limit will never trip with values greater than 2.7bar in the map. In this case you can create a custom map for fuel cut against the Inlet Manifold based MAP sensor.

Multiplier (bar/volt): 0.613

Offset (bar): -0.235

0.613bar x 5 volt = 3.065bar

3.065bar – 0.235bar Offset = 2.83bar (for the standard MAP Sensors)

Multiplier (bar/volt): 0.83

Offset (bar): 0

0.83bar x 5 volt = 4.15bar

With zero Offset value the AMS sensors are rated at 4.15bar Absolute.

As you can see its possible to calibrate the input voltage values as well as the output pressure values.

TCM Tuning

The Nissan GT-R TCM is at the heart of the GT-R driving experience and delivers excellent control of the Ricardo 6 speed dual clutch transaxle. The TCM controls the pressure applied to both of the clutches in the gearbox, while accurately positioning the selector forks to select gears in two gear clusters. The TCM is tightly linked to the ECM and together they deliver much of what makes the GT-R driving experience what it is.

An in depth understanding of the GR6 transmission can be had by comprehensive reading of the Nissan technical service manual that describes the mechanical operation, and many diagnostic functions and information. For detailed service and diagnostic information please refer to section TM “Transaxle & Transmission” in the Nissan R35 GTR service manual.

Some aspects of operation are useful to know in the tuning and calibration of the TCM maps to improve the driveability and/or performance to compliment power upgrades and transmission hardware changes. Understanding the live data and how to interpret it is an important step in successfully tuning the TCM.

For additional information check out the GT-R TCM Tuning Guide

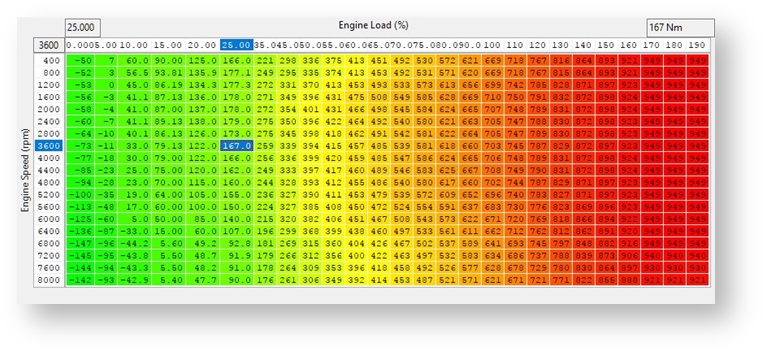

Torque

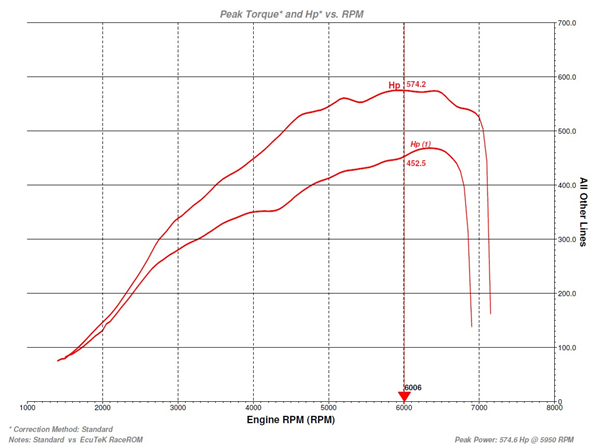

Introduction

The GT-R uses torque extensively for interacting with the TCM and VDC systems, but the 16x16 OEM map used as the basis to calculate torque only accommodates with load values up to 100% which can be exceeded by a stock car running increased boost. To overcome this issue RaceROM adds a new 26x19 map that uses a high precision load input that allows any load value to be used. This gives more accurate torque values at low loads while catering for torque values that can increase with engine loads seen on 1500hp cars.

It is important to understand that torque is derived from load, which is an expression of estimated airflow, so proper operation of the torque model relies on accurate tuning of the MAF or SD and injectors. Errors in the resulting torque of just 10% can give poor shifting feel, so efforts need to be made to ensure that errors in injector scaling are not covered up by poorly calibrated MAF or SD VE maps, or vice-versa.

Torque Actual (RaceROM)

The default values are calibrated to give results that offer as close to stock behaviour as possible within the range of the stock map. The areas most likely to benefit from fine tuning are in the part throttle zones, and even on cars which have well calibrated fuelling and airflow, tuning this can be of benefit to iron out some odd TCM behaviours.

This map should not however be used as a band-aid to fix a general trend of slipping clutches. Specific tuning of the TCM should be used on cars that have issues holding the peak torque the engine can deliver.

Map List

Live Data Parameters

- Torque Actual – Final Torque actual value after compensations, usually different to values in map

Upshift Boost Spike Prevention

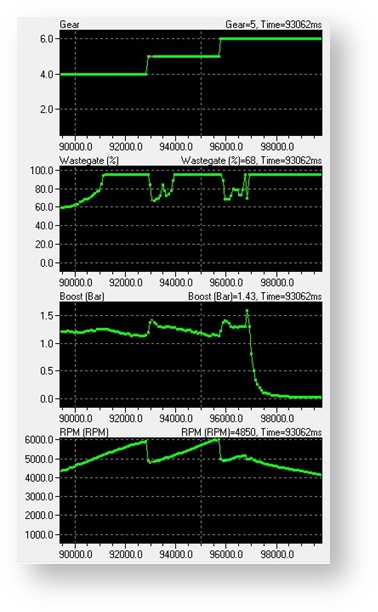

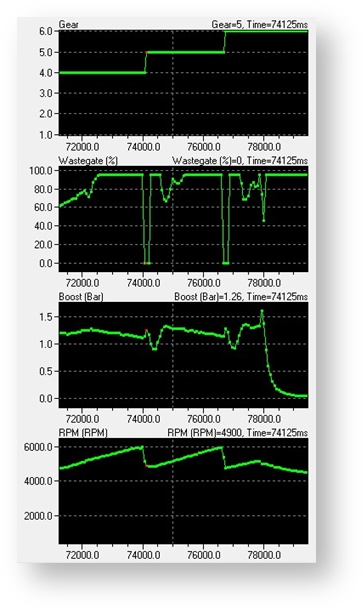

When the vehicle shifts into a higher gear, the sudden reduction in engine RPM can cause a momentary but substantial increase in boost pressure. The Upshift Boost Spike prevention feature can help to prevent this spike by reducing wastegate duty during the shift. (see screenshot below for a before and after comparison). This problem is exaggerated at higher boost pressures and also with larger turbo’s fitted.

Larger turbos will take long to respond than the stock turbos.

Without USP - Spike to 1.43bar

With USP - Spike reduced to 1.26bar

Enable Special Features

This map contains the Enable Upshift Spike Prevention checkbox to enable this feature.

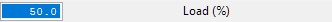

USP Wastegate Multiplier

This 3D map allows you to specify a multiplier for the wastegate duty based on the current boost pressure and the time period after the gear change in milliseconds (ms). The wastegate duty will be multiplied by this value during/after an upshift has been performed.

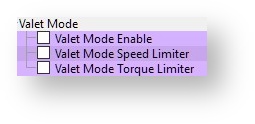

Valet Mode

Introduction

Valet Mode allows the driver to lock the car into a lower performance mode when lending it to a less experienced driver, or as a theft deterrent that kicks in when the car is at a safe distance. Valet mode has been simplified in line with the strategy used on the 370z, as the previous version was frequently commented on as being too complicated to activate and deactivate. Valet mode is operated using the cruise control switches in the same way as map switching. Instead of selecting map switch mode 1, 2, 3 or 4, select mode 8. The map switch mode does not change.

Map List

To turn on the Valet mode

- Ensure that the cruise control is OFF.

- Hold the CANCEL button for 1 second.

- The rev counter will move to indicate the current mode.

- Use the cruise up button until the tachometer shows 8000rpm (mode 8).

- Press CANCEL or wait 1 second to enable the valet mode, the rev counter will show current RPM

To turn off the Valet mode

- Ensure that the cruise control is OFF.

- Hold the CANCEL button for 1 second.

- The rev counter will move to indicate the current mode.

- Use the cruise up button until the tachometer shows 8000rpm (mode 8).

- Press CANCEL or wait 1 second to enable the valet mode, the rev counter will show current RPM

Please take note that Valet Mode activation is now a toggle and it’s relatively easy to activate. Car owners can in some cases activate it accidentally and it’s not been unknown for car owners to end up at a main dealer to have their “problem” fixed!

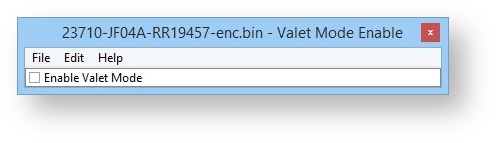

Valet Mode Enable

The "Enable Valet Mode" checkbox enables operation of the Valet Mode feature.

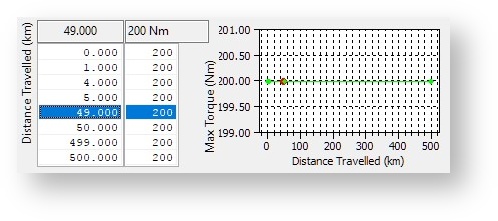

Valet Mode Torque Limiter

When Valet Mode is active the torque output can be limited to prevent a car being driven hard or recklessly. For use as an anti-theft measure it would be reasonable to reduce these values from the default 200Nm after a short distance.

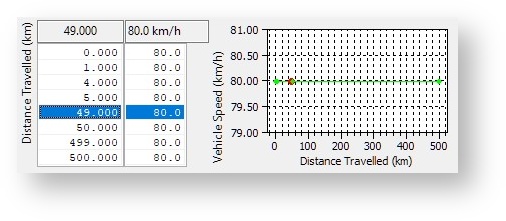

Valet Mode Speed Limiter

When Valet Mode is active the maximum speed can be limited to prevent the car from being driven at anything beyond a sedate pace. For use as an anti-theft measure it would be normal to significantly reduce these default values to as low as zero after a shorter distance.

EcuTek ProECU tuning tools tools should only be used by experienced tuners who understand the product and engine calibration.

If you do not fully understand this product then you WILL damage your engine, ECU or your vehicle.

Please ensure you fully read all EcuTek manuals BEFORE attempting to use ProECU with your laptop or your vehicle.

Use with extreme caution and understanding at all times, if in doubt then do not proceed.

EcuTek accepts no responsibility for any damage to the engine, ECU or any part of the vehicle that results directly or indirectly from using the product.

** If you are in any doubt that you do NOT have the experienced required to use this product then you should NOT USE IT **

Retail customers

** If you have any doubt that you do NOT have the experienced required to use this product then you should NOT USE IT, you should simply contact your EcuTek Master Tuner shown clearly on the top of your Programming Kit or visit your preferred tuning shop to have a professional tuner to use it for you **